Mr. Gautam Ghosal is a subject matter expert in the plumbing discipline and foremost authority on issue relating to plumbing systems installed in buildings. This article on water hammering, penned by Mr. Ghosal, offers tremendous insights into the causes of water hammering.

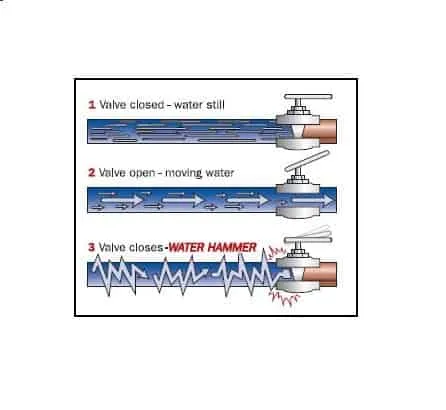

Water hammer can be recognized by a big “thump” that causes vibrations in the house or a part of the house or in the pipe lines. It could also be a series of such effects continuing for a period of time. A typical illustration of how a water hammer is caused is shown in the diagram below.

HOW IS WATER HAMMERING CAUSED

Water hammer occurs when the flowrate of fluid in the pipe changes rapidly. It is also known as “surge flow”. This generally happens when there is rapid closure or opening of a valve. For an average person, it would suffice to say that when there is noise while opening a valve, it could possibly be due to air in the piping system, however when the noise occurs after the closure of a valve, it is water hammering. It will also be worth mentioning that closure of even a single lever faucet does cause the water inside the pipe to gain a certain amount of turbulence although there may not be any sound or vibration etc. that is detectable.

Rapid or quick closure of valves effectively means that the closure is not smooth or regulated. In residences and commercial complexes, all single lever faucets and diverters, WC and Urinal Flush Valves, Health Faucets and the Washing Machine and Dishwashers are common sources are causes of water hammering. Since water hammering quite depends on the water flow rates or the velocity of water besides the rapidity of closure, the Flush Valves, Health Sprays, the Washing Machine and Dishwashers become largely suspect in being the cause for detectable water hammering.

Modern day luxury fittings and high rise residential and commercial structures incorporate the phenomena of water pressure. Hence hydro-pneumatic systems as well as high gravity head are becoming common. Consequently water velocities are higher and the use of quick acting Pressure Reducing Valves are in vogue. Both of these are sufficient pointers towards the occurrence of water hammering and the need to carefully design the piping systems.

OTHER CAUSES OF WATER HAMMERING

Water hammer can also be caused when a valve is suddenly closed or a pump trips due to power failure or high load. Cavitation results due to the pressure dropping below the vapour pressure and then the bubbles collapsing as the pressure is restored. The liquid flows backward and when it collides with the valve or pump, severe hammering can take place. Possible locations for such occurrences are after the valve or downstream of a pump.

Closure of non-return valves can also cause water hammer. Even a simple swing check valve can cause substantial water hammer.

WHAT REALLY HAPPENS

Water hammer is then a shock wave passing down the pipe as a result of a sudden flowrate change. The most common causes for hammering could be a valve closing too quickly, or a pump tripping or starting up suddenly. A shock wave commencing at the valve or pump passes along the pipe and changes the water velocity as it travels resulting in high pressure. A high magnitude shock wave when passing through pipe bends or any other diversion causes forces which act on the pipe resulting in the movement of the pipe. The result – from very small vibrations to forces that might cause the pipe to move off its supports or transmit the force to its anchors or even travelling through pumps, damaging the impellor and drive.

Pressure fluctuations happen every time water is accelerated or retarded by changes in pump conditions i.e. start or shut down or by changes in valve position that is open or close. Under normal circumstances the rate of change is gradual and the water hammer effects cannot be detected easily. But under certain conditions and by the use of certain equipment like flush valves and solenoid valves, the pressure created can be high enough to cause severe rattling of pipes thereby causing damage to pipes and equipment. To sum up, the effects could be as follows:

- Damage to pipe fittings and valves or any connected equipment causing leaks and shortening the life of the system.

- Bursting of pipes if the pressure is high enough

- Water hammer can have devastating effects on pump system

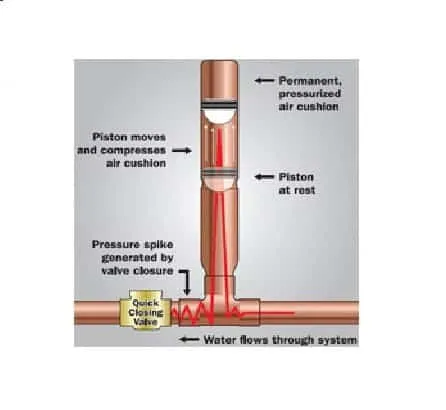

WATER HAMMER ARRESTORS TO PREVENT WATER HAMMERING

While there are established methods of analysis of water hammer which most often should be taken care in the course of the design of the piping system and some common solutions like installation of air chambers and surge tanks, mechanical water hammer arrestors are also an effective method of prevention of water hammering.

Arrestors are sealed units with a spring and air bladder to absorb the water movement, and mitigating the water hammer effect. They are the preferred alternative in commercial buildings and when used for high water pressure applications. Mechanical water arrestors do not need to be recharged like air chambers and incorporate a permanent pre-charged sealed air chamber to absorb the shock. The sealed chamber prevents the loss of air to the water and ensures long and trouble-free life. All potential leak points are permanently sealed.

It is also worth mentioning that the UPC-Uniform Plumbing Code 609.10 and the IPC-International Plumbing Code 604.9 both recommend the installation of Water Hammer Arrestors where quick closing valves are utilized.

The requirement is assessed on the basis of the fixture units consequent to the equipment being used and the pipe line size and the corresponding hammer arrestor can be easily determined. Manufacturers have typical reference tables to help piping designers identify the appropriate water hammer arrestor.

The water hammer arrestor is recommended to be located at the end of the branch line between the last two fixtures served. The location of the water hammer arrestor shown above applies to branch lines that do not exceed 20 feet in length, from the start of the horizontal branch line to the last fixture supply on this branch line. When the branch line exceeds the 20 foot length, an additional water hammer arrestor should be used.