Cladding is a term used to describe components that are affixed to a building’s basic structure to create non-structural external surfaces. Cladding is done on interior as well as exterior walls in different materials like wood, stone, ceramic tiles, ACP, metal, etc.

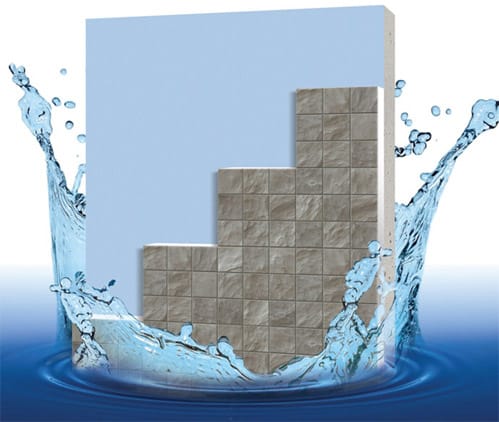

The practice of laying one material on top of another to produce a covering over the walls is known as wall cladding. It is used to prevent water from damaging the walls and interior workings of a room or building, as well as allowing water to flow into the structure that is a potential hazard to persons moving around inside the building.

Wall cladding is available in several types and forms with different materials, textures, and dimensions. Also, cladding systems include additional components, such as windows, doors, gutters, roof lights, vents, and so on.

Image Source: renew.org.au

The type of cladding used for a specific structure will be determined by factors such as:-

- The purpose of the building

- Internal and external factors

- Durability

- Requirements for planning

- Building regulations

- Local context

- Accessibility and constructability

- Appearance as well as availability

- Budget

- Requirements for maintenance

- Requirements in terms of structure

Advantages

- Increases a structure’s mechanical strength.

- It both protects and beautifies the underlying structure.

- Thermal insulation is improved.

- Also, serves decorative purposes.

- Increases the temperature while improving crack resistance.

- Reduces the amount of water absorbed.

- Provides resistance to sunlight.

- Protection from the air and chemical pollutants.

- Provide appropriate acoustics for sound absorption and insulation.

Types and materials

Cladding is made of a wide range of materials including wood, metal, brick, vinyl, and composite materials that can include aluminium, wood, blends of cement, and recycled polystyrene.

Natural stone cladding

The cost of natural stone cladding is mainly determined by the type of stone purchased, such as slates, sandstones, marble, granites, limestones, and quartzites. The price is also heavily dependent on the needed form and size. Stone strips ranging from 2 to 15 rows are used to create cladding. As a result, the more pieces in a single stone cladding, the more glue is necessary to adhere them together.

Vinyl cladding

It comes in a variety of colours to choose from. Because vinyl is still one of the most affordable cladding materials and has been proven to be energy efficient, it can save you money not only during the installation process but also in the long run. Panels can also be fitted with an additional layer of insulation, creating a temperature-controlling blanket that keeps your home warm in the winter and cools in the summer. Vinyl is significantly lighter than its counterparts, allowing panels to be entirely flexible when covering a building. It is dent- and flake-resistant, and it does not require re-painting.

Aluminium cladding (ACP)

When compared to other metals, ACP or aluminium cladding has a lot of advantages. Aluminium is approximately one-third the weight of steel. It weighs about 2,7g/cm3 on average. This makes aluminium an excellent building material, as it will survive for decades. It is recyclable and will not degrade in quality during the process. Aluminium is constantly released, and the process consumes very little energy. ACP cladding is easily molded into a variety of shapes, sizes, and finishes, making it a versatile material.

Wood cladding

Wood continues to be one of the most aesthetically beautiful paneling materials available. Timber cladding is commonly installed in long, narrow boards that can be installed horizontally, vertically, or diagonally, and the end result can be completely tailored to create the desired ornamental finish. Wood is weather-resistant and an excellent insulator, making it ideal for siding. It’s long-lasting and simple to set up. Wood’s natural appearance has an unrivaled aesthetic quality. Wooden planks can also be used for decking and flooring.

Brick cladding

Cladding in bricks is done with lightweight materials and comes in a variety of colors. It offers complete protection against all elements to which it may be exposed. Brick cladding will not fracture, degrade, or exhibit symptoms of pollution damage. The majority of cladding bricks are made with a proprietary, state-of-the-art machinery created in-house. In the winter, it provides energy-efficient warmth, while in the summer, it keeps you cool. They work in tandem with passive building design to harness natural energy sources. Brick cladding’s natural density and thermal insulating properties help to maintain a comfortable building temperature while lowering energy use.

Fiber cement cladding

It is made up of sand, cement, and cellulose fibers for reinforcement. These panels are used to clad the external walls of residential, commercial, and industrial structures. They’re available in planks and panels, with a variety of texture options. These are meant to seem like longer timber planks and are commonly used in construction. Dimensional stability is one of the most appealing features of this wall covering system. Unlike exterior wall cladding panels made of standard materials, these do not compress and expand.

Glass cladding

It is suitable for inside and outside of a building. It’s a practical and budget-friendly alternative to tiling, painting, and other types of decors. These forms of cladding can create a visually appealing, easy-to-maintain wall surface that is suitable for a variety of commercial interior and exterior applications. Tempered, laminated, enameled, curved, and specially treated glass are among the many glass cladding alternatives available, each with great versatility in terms of look, performance, and composition to meet modern architectural needs.

Ceramic or tile cladding

Ceramic cladding, also known as tile cladding, offers additional support for ceramic tiles. It has several advantages, which is why it is in such high demand. These claddings are extremely resistant to adverse weather and are not easily destroyed. They can last for many years without showing any signs of wear. Rain, as well as rising pollution levels, have little effect on them. Furthermore, because they are resistant to damaging UV rays, they are an excellent choice for your structure. It is composed entirely of natural materials and is thus environmentally friendly. It is easily recyclable and contributes to the reduction of carbon footprints in the environment.