A brick might be a small part of a construction building, but an integral one. Builders, developers, architects and designers must know the properties, consistency and stability that these bricks provide for optimal outcomes. Along with being a primary element in the construction of residential buildings to monumental skyscrapers, bricks also add to the aesthetic value. Their sizes and dimensions, including brick sizes in inches and cm, vary based on several factors such as region, climate, customised requirements etc. This article dwells into the types of bricks, standard dimensions and sizes of bricks in India and across the globe, clay bricks, factors to consider to choosing the correct brick and much more.

Contents

- 1 Standard dimensions and sizes of bricks in India

- 2 Standard dimensions and sizes of bricks by region

- 3 Types of bricks

- 4 Types of bricks used for different parts of construction

- 5 Lifespan of various types of bricks

- 6 All about clay bricks

- 7 How are brick dimensions measured?

- 8 How do I choose the right brick size for construction?

- 9 FAQs

- 9.1 Do standard dimensions and sizes of bricks affect mortar joint thickness?

- 9.2 How do regional variations in brick sizes impact construction practices?

- 9.3 Does a building’s overall strength depend on the size of the bricks?

- 9.4 Are bricks naturally water-resistant?

- 9.5 Can the standard sizes of bricks be customised?

- 9.6 Do the standard sizes of bricks shrink over a long duration of time?

- 9.7 Do the standard sizes of bricks affect the load-bearing capacity?

- 9.8 What is the lifespan of standard bricks?

- 10 Selecting bricks: Types, standard dimensions & prices in India

Standard dimensions and sizes of bricks in India

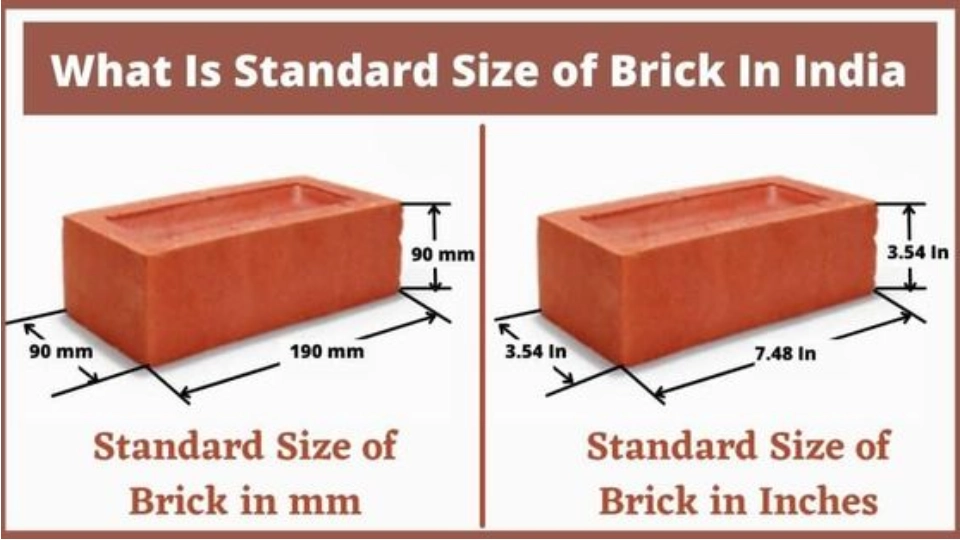

The standard brick size(converted into inches or cm if needed) in India is 190 mm long x 90 mm wide x 90 mm high. This brick standard size in India is commonly followed in construction, ensuring uniformity and consistency across building projects.

Standard dimensions and sizes of bricks by region

| Country | Standard sizes of bricks |

| India | 190 mm x 90 mm x 90 mm |

| United Kingdom | 215 mm x 102.5 mm x 65mm |

| Australia | 230 mm x 110 mm x 76 mm |

| China | 240 mm x 115 mm x 53 mm |

| Bangladesh | 225 mm x 112.5 mm x 75 mm |

| Japan | 210 mm × 100 mm × 60 mm |

| USA | 194 mm × 57 mm × 92 mm |

| Germany | 240 mm × 115 mm × 71 mm |

| Russia | 250 mm × 120 mm × 65 mm |

| UAE | 215 mm x 102.5 mm x 65 mm |

Types of bricks

Sun-dried bricks

Sun-dried bricks or mud bricks are the most basic type of all. As the name suggests, they are dried in the sun for moisture absorption and hardening. They are mostly used in rural areas and for temporary construction. Sun-dried bricks are the least durable type and not very expensive. They are sometimes used for decorative purposes too.

Advantages

- Eco-friendly: These bricks are made of natural materials that are easy to decompose and do not impact the environment.

- Easy to make: Sun-dried bricks do not require any technological methods for manufacturing. It uses the traditional methods.

- Economical: These bricks cost the least as they do not require costly tools and materials.

Disadvantages

- Labour intensive: Sun-dried bricks are made using traditional manual methods. This method relies highly on labour and physical effort.

- Time-intensive: Considering the sun is the only source of drying, the processing time of sun-burnt bricks is significantly greater than that of other bricks.

- Durability: These bricks are not suitable for multi-story buildings since they are relatively less durable than burnt bricks.

Burnt clay bricks

Burnt clay bricks are also called common bricks as they are the most common bricks in use. They are used in columns, walls and foundations. They are available in various sizes, shapes and colours. Burnt clay bricks have high compressive strength and are available in four categories, first, second, third and fourth-class bricks.

Advantages

- Strength: These bricks are used in load-bearing walls and other structural applications since they can sustain substantial loads.

- Versatile: These bricks are suitable for both aesthetic and structural applications.

- Highly durable: They are perfect for structural and decorative applications because they are impervious to weathering, fire, and deterioration.

Disadvantages

- Heavy: Compared to other building bricks, burned clay bricks are comparatively hefty.

- Environment impact: Carbon dioxide emissions from the manufacturing process contribute to environmental pollution.

Fly ash bricks

Also called self-cementing bricks, fly ash bricks are made from a by-product of coal. They are used in the construction of pillars and walls. Fly ash bricks are lightweight and an eco-friendly alternative compared to the other types. They have high compressive strength and lower water penetration.

Advantages

- Thermal insulation: Fly ash brick buildings are better at regulating inside temperatures, which lowers heating and cooling energy expenses.

- Fire and sound resistance: Because fly ash bricks are non-combustible, they provide exceptional fire resistance, adding an extra degree of security.

Disadvantages

- High water absorption: Problems like moisture and efflorescence can erode a building’s structural integrity over time.

- Lack of uniformity: Inconsistency may result in uneven walls and necessitate the use of additional mortar to fill up any gaps when building.

Concrete bricks

Concrete bricks are made from mixtures of cement, sand and water. This brick aids in lowering the quantity of mortar required for building. These bricks are incredibly durable and weather and fire-resistant. They are frequently utilized as paving stones and for load-bearing buildings because of their improved insulating qualities.

Advantages

- Strength: It has a high compressive strength since it is composed of cement, sand, and aggregate.

- Versatile shapes: These bricks made of concrete are available in various shapes and dimensions(standard and customised) and can be used for anything from flooring to walls to foundations.

Disadvantages

- Expensive: Comparatively, concrete bricks are more expensive than others.

- Aesthetics: Concrete blocks lack aesthetic appeal so people avoid using them outside houses.

Sand lime/calcium silicate bricks

As the name suggests, these bricks are made of sand and lime that helps to harden. These bricks are chemically set and feature a smooth surface, good fire resistance, and acoustic insulation. They can be used where thermal insulation is crucial, such as high-rise buildings. Additionally, their homogeneous appearance makes them ideal for enhancing a building’s visual appeal.

Advantages

- Sound insulation: Sand lime bricks are perfect for residential and commercial buildings in loud areas because of their high density, which provides good sound insulation qualities.

- Eco-friendly: Compared to other bricks, the manufacturing process is environmentally friendly.

- Aesthetic appeal: Bricks made of sand lime come in various shades and textures.

Disadvantages

- Temperature resistance: These bricks have relatively low heat tolerance, therefore, they cannot be used in kilns, fireplaces etc.

- Weight: These bricks are heavy, which makes handling more difficult and raises shipping expenses.

Engineering bricks

Engineering bricks are sturdy, dense, and impervious to chemicals and water because they are created from premium clay that is burnt at extremely high temperatures. What distinguishes engineering bricks from others is their exceptional durability. Because of their extremely low porosity, they are utilized in applications where resistance to water and frost is essential, such as subterranean tunnels, retaining walls, manholes, and foundational work.

Advantages

- Longevity: The extended lifespan of engineering bricks reduces the need for frequent repairs or replacements due to their weather resistance.

- Durability: Under pressure, engineering bricks don’t break or get damaged quickly.

- Versatile: These bricks can be used for construction projects, including covered ground maintenance holes, soil-retaining walls, and foundations.

Disadvantages

- Cost: Engineering bricks are more expensive due to their features like weather resistance, durability etc.

- Fading colour: Due to prolonged exposure to the sun, engineering bricks tend to lose colour.

Fire bricks

Another name for these is refractory bricks. Because of its fire-resistance qualities, it can tolerate extremely high temperatures. This is used to line furnaces, kilns, fires, and chimneys, places where temperatures are typically very high.

Advantages

- Superior insulation: Due to their temperature tolerance, fire clay bricks are perfect for high-heat applications.

- Durability: Given their exceptional durability, they can withstand harsh environments for many years without suffering major wear or damage.

Disadvantages

- Environmental impact: Fire bricks are made from natural resources like silica and alumina and release smoke during manufacturing.

- Weight: The heavy weight of fire bricks makes transportation and logistics difficult, indirectly impacting the overall project cost.

Types of bricks used for different parts of construction

- Foundations: Engineering and burnt clay bricks are usually used for foundations due to their strength, durability and longevity. Due to their low water absorption properties, they are perfect for construction sites.

- Flooring and paving: Engineering bricks are used in pavements as an alternative to cement due to their resistance to water, durability and aesthetic appeal.

- Partition walls: Concrete bricks are a good choice for partition walls as they provide great sound insulation with other properties like water absorption, heat resistance etc.

- Aesthetic walls: Aesthetic walls can be made using fire ash bricks, which have distinctive colour variations and a natural, rustic look. They have a unique, textured appearance in addition to being useful.

- Fireplaces: Because of their remarkable resistance to high heat, fire bricks are a common choice for fireplaces. They keep heat from leaking and offer superior thermal insulation.

Lifespan of various types of bricks

| Brick type | Lifespan |

| Sun-dried | 15 to 25 years |

| Burnt clay | Over 100 years |

| Fly ash | Approximately 100 years |

| Concrete | 50 to 100 years |

| Sand lime/calcium silicate | 20 to 30 years |

| Engineering bricks | Over 150 years |

| Fire bricks | 60 to 70 years |

All about clay bricks

The popularity of common clay bricks can be attributed to their adaptability and versatility. They are also fireproof, strong, and long-lasting. Bricks are inexpensive and easy to utilize due to their weight and size. Housing and office buildings, retaining walls, and columns are common constructions that may be built with clay bricks. Depending on the quantity of various components contained, clay bricks come in many colours. Red, brown, and pink are some of the most popular colours for clay bricks. The size of bricks varies by country, thus it usually relies on the location. The standard size of any clay brick in India is typically 9 inches(length), 4.5 inches(width), and 3 inches(height).

Additionally, it may be influenced by the manufacturer and the region from where you purchase. Similarly with clay bricks, the texture, and colour might vary from place to place. The diversity and versatility of clay bricks are the main properties that enable the builders or architects to achieve the desired result.

How are brick dimensions measured?

The following formula can be used to obtain a more precise estimate of the brick size: (brick height (m) x mortar joint width (m) / (wall height (m) x wall length (m)(brick sizes can be converted into inches or cm if required). For different building components, choosing the right kind of brick is crucial to guaranteeing solidity in construction, longevity, and visual appeal.

How do I choose the right brick size for construction?

The standard brick size in India is typically 190 mm long, 90 mm wide, and 90 mm high(brick sizes can be converted into inches or cm if required). This brick size is widely utilized in Indian architecture. To get the style you want, it’s crucial to consider the colour, texture, and laying patterns of the bricks you choose for your house. A building’s appearance and feel may be greatly influenced by even the slightest elements, and picking the proper brick can have a big impact.

Because of their extraordinary strength and endurance, engineering bricks are the best option for foundations. Bricks made from burned clay are frequently utilized because of their durability and insulating qualities. Fly ash bricks are also appropriate since they are environmentally benign and lightweight, which lowers the overall structural load and promotes sustainability. Fire bricks are essential in regions with high temperatures, such as chimneys and fireplaces. Fire bricks preserve building integrity and guarantee safety in such conditions since they are made to resist extremely high temperatures without deteriorating.

In conclusion, this article highlights the different types of bricks, their sizes and dimensions across the globe, factors influencing the brick dimension and size(in metres, inches or cm) etc. Understanding the standard sizes and dimensions of bricks in India and abroad is a necessity for a builder an architect or even someone who is about to construct a house or structure. The sizes and dimensions, types and orientations may vary from one region to another. However, the correct brick certainly has to be chosen for it, to serve both the purposes of functionality and aesthetics. Additionally, as the infrastructural practices progress so rapidly around the globe, ensuring sustainability in all such practices becomes vital too.

FAQs

Do standard dimensions and sizes of bricks affect mortar joint thickness?

Yes, the standard dimension and size of any brick(in inches, mm or cm) affect mortar joint thickness. The mortar joint thickness is also affected by the type of brick used. During construction, the ideal mortar joint size should be considered for proper bonding and stability of the structure. To reduce wastage, properly plan the usage of materials.

How do regional variations in brick sizes impact construction practices?

The standard sizes of bricks vary by country, affecting the construction process. As larger bricks need less amount of mortar joint moulds but are heavy, smaller bricks are easy to carry but require more units. As it depends on the availability of raw materials in a specific region, the size, texture and type of the bricks may vary.

Does a building’s overall strength depend on the size of the bricks?

Yes, when more layers are added to the bricks, they become thicker in size, thereby, increasing the load-bearing capacity of the structure. The thicker the bricks, the thicker the walls, making it difficult to penetrate and damage completely. The compressive strength of the bricks is also a significant factor in determining the strength of the wall.

Are bricks naturally water-resistant?

No, bricks are not water-resistant or waterproof and are made for application in construction areas with water or moisture content. Bricks could be treated to make them more water resistant. Bricks can absorb water content which can cause potential damage over time. Therefore, it is ideal for the bricks to be kept as dry as possible.

Can the standard sizes of bricks be customised?

Yes, bricks are available in custom sizes, colour mixtures and finishes. They are available in their standard brick size of various measurements such as cm and inches. They provide a range of preferences and options for customers to choose from. Bricks could be customised depending on the construction requirements and specific needs of the project.

Do the standard sizes of bricks shrink over a long duration of time?

Bricks made from cement or concrete tend to shrink over long durations. However, bricks made using clay expand. Although bricks do not significantly shrink over time, they experience minute changes due to external influences such as wear and tear, pollution and internal factors like moisture absorption capabilities.

Do the standard sizes of bricks affect the load-bearing capacity?

Yes, the size and number of bricks used, affect the structure and therefore the load-bearing capacity. If the bricks are placed uniformly throughout the structure, they contribute to the load-bearing capacity. The bricks can support better when they are evenly distributed without causing damage. The stronger the layers of bricks more is the stability of the building.

What is the lifespan of standard bricks?

A standard brick is estimated to last from over 100 to 150 years. Even though bricks are known for their longevity, it is recommended to maintain them well to enhance their lifespan. To maintain the appearance of the bricks, it is necessary to regularly remove the debris that accumulates over time.

*The featured image used in this article is from Pinterest.com

Selecting bricks: Types, standard dimensions & prices in India

When it comes to construction, bricks have gained an edge over other building materials like wood. Bricks are a type of block