Edge bands, also known as edge banding tapes are finishing materials found in the majority of furniture and cabinetry, used to cover the raw edges of wood, plywood, particle board, or MDF panels. It gives a sleek appearance, usually offering protection against moisture, wear, and chipping. Edge bands are usually made of PVC, ABS, wood veneer, or melamine and are available in various colours, textures, and sizes, most of which are matched or complemented with the colour pattern of the surface of the panel. They are used to enhance the durability, aesthetics, and functionality of furniture for both homes and offices. Moreover, these are important for achieving seamless, professional-quality furniture designs. Also, explore all about REHAU edge banding in this article.

Types of edge bands

On the basis of materials

PVC edge bands

Image Source: justdial.com

Theese are the most commonly used because of their flexibility, durability, and cost-effectiveness. They are also resistant to moisture, chemicals, and wear, making them ideal for kitchens, bathrooms, and furniture. The array of colours, textures, and finishes PVC edge bands offer are fabulous. They include woodgrain and solid colours, making them fit well with most surfaces.

ABS edge bands

Image Source: maxavegroup.com

These edgebands are an environmentally friendly alternative to PVC. They are light in weight, and non-toxic, with high durability. Known for their impact resistance and heat stability, ABS edge bands are suitable for furniture in environments that demand high sustainability standards, such as schools and hospitals. Their smooth surface makes working easy during application.

Wood veneer edgebands

Image Source: amazon.in

These edgebands are made of very thin slices of real wood and give a perfectly natural and authentic look. They are suitable for traditional or luxury furniture designs where one needs to keep a consistent look. A wood veneer edge band is made from various kinds of wood like oak, maple, or walnut, and can be stained or varnished to match furniture.

Melamine edgebands

Image Source: richies.in

These edge bands are made from resin-impregnated paper. They are light in weight and cost-effective. Melamine is extensively used in low-cost furniture or lightweight panels. Despite not being as strong as PVC or ABS, they have a neat finish and are available in various colours as well as patterns.

On the basis of finishes

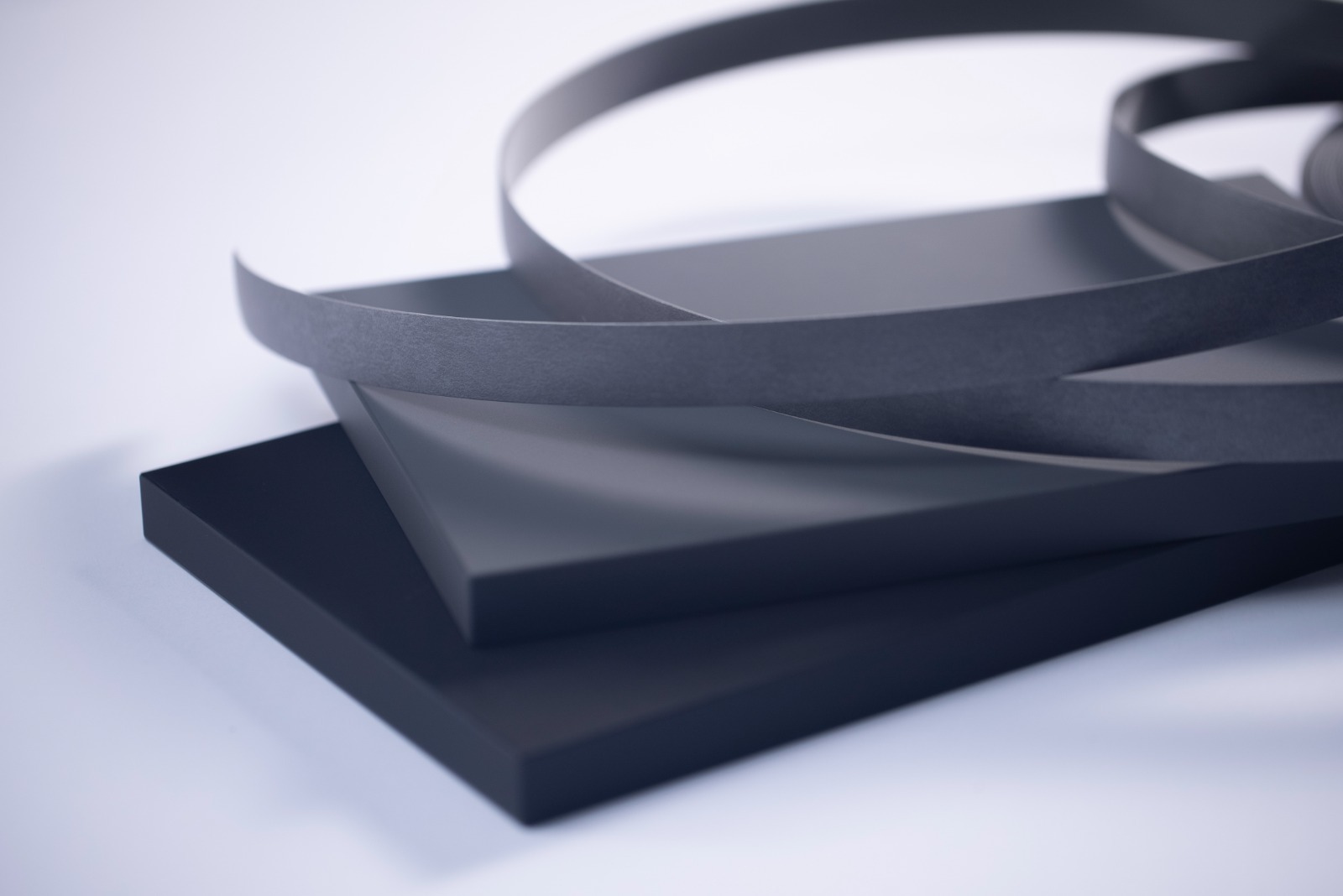

Solid matt

Image Source: amazon.in

Applying solid edge bands with a matte finish gives furniture edges a sleek, durable, and seamless finish. These bands are made from high-quality materials like PVC or ABS, giving them a smooth finish, and providing a modern and classy appearance. It is available in different solid colours to suit different styles of furniture design and decor themes.

High gloss

Image Source: woodzon.com

High-gloss finish edge banding comes with a very shiny, reflective touch to furniture edges, making all of it look lovelier and modern. Made from materials like PVC or ABS, these edge bands feature a glossy surface that provides a polished and luxurious look.

Wood grain

Image Source: alibaba.com

These edgebands are specifically designed to try and mimic the look and even the texture of natural wood, meaning that the edges of furniture acquire a warm, authentic wooden look. Made from PVC, ABS, and veneer, these edge bands feature realistic-looking wood grain patterns in various kinds of furniture.

Fabric textured

Image Source: edgebands.com

Fabrics have textured finish edgebands that give the furniture its unique and fashionable look. The long-lasting edgebands are made from either PVC or ABS materials which provide a three-dimensional texture with the textile tactile element in furniture edges. Edgebands have many designs inspired by fabrics of various colours so there is much creativity since they are open to possibilities.

3D edge band

Image Source: amazon.in

The 3D finish edgebands are solutions at the edges, producing an amazing depth with a three-dimensional effect on furniture edges. Available from premium materials like PVC or ABS, these edgebands feature a transparent or textured top layer, enhancing the appearance with a realistic 3D visual impact.

Application areas

Modular furniture

Edge bands are highly used in modular furniture, such as cabinets, wardrobes, and kitchen units. It provides a clean and shiny finish to MDF, plywood, or particle board edges, increasing strength and aesthetics. The variety of textures and colours available allows designers to match or contrast the surface, adding style to modular setups.

Office furniture

The PVC and ABS edgebands are fixed along the edges of workstations, desk partitions, and conference tables, ensuring safety and durability. They prevent impacts or scratches caused by frequent usage on the edges. Due to their durability and resistance to wear, these edgebands have become popular for office furniture.

Retail and display furniture

Retail shelving units, counters, and display cases need edgebands for both aesthetics and functionality. The choice usually comes across acrylic edgebands the most; as they add a high-gloss and vibrantly coloured finish to the designs. Simultaneously, they protect furniture from heavy wear which is common in commercial environments.

Bathroom furniture

In bathrooms, vanity cabinets, and storage units are typically made of moisture-resistant edge bands so that they do not swell or warp because of the moisture in the room, ensuring furniture remains functional and visually appealing over time. Ideally, ABS and PVC edge bands could be used for such functions.

Hospitality industry

Hotels, cafes, and restaurants use edgebands on the tables, counters, and storage units to express a professional look and style. In addition to this aesthetic function, these ensure durability by protecting furniture against spills, impacts, and scratches.

Edge banding process

Edge banding is the technique used for sealing and strengthening raw edges of furniture panels by giving a glossy finish and improvement in strength. The process begins with cleaning the panel edges to ensure they are smooth and free from dust. Secondly, a suitable edgebanding material like PVC, ABS, or veneer is chosen based on the required finish and intended application. Using some adhesive, usually hot-melt glue, it is attached to the edge of the panel surface using a device called an edge bander or handheld tools. After bonding, any excess material is carefully trimmed, and the edges are polished for a seamless, professional finish. This process not only improves the aesthetics of furniture but also protects the edges from wear and moisture.

REHAU edge banding tapes

After seven decades, the edge banding tapes are still an integral part of REHAU furniture solutions, just like the company’s constant values: consistent reliability, adaptable designs, and an innovative spirit admired by its partners. REHAU RAUKANTEX pro-invisible-joint edge bands and similar patented REHAU designs have transformed the kitchen and bath furniture industry. The edge bands manufactured by REHAU are suitable for many applications like cabinets, wardrobes, countertops, and office furniture. They provide an even finish, protect the edges from wear and tear, as well as moisture, and help to enhance durability.

Features of REHAU edge banding tape

The features of REHAU edgebanding tape are:

- 1,000+ designs: A vast collection of edgeband designs to suit every furniture need.

- 300 active designs: A continuous supply of active designs available.

- 200 new additions annually: Regularly updated with fresh and innovative design collection every year.

- 20,00,000+ custom options: Infinite possibilities through the combinations of materials, their sizes, patterns, finishes, and methods of application.

Range of REHAU edge bands

- Zero-joint: REHAU Zero Joint Edge band comes with an already attached polymer functional layer, which in turn eliminates the use of any glues, hence enabling achieving a completely optical as well as functional zero joint between the edgeband and the board.

- Decorative: REHAU India offers approximately 395 colours and decors with different embossings

- Mirror-gloss: Experience the stunning aesthetic of high gloss finishes with REHAU’s Ultimate Gloss edgebands as the reflective quality is above 85 points.

- 3D effects: REHAU edge banding requires no machine adjustments, making them easy to use. They provide room for creative designs, particularly with the RAUVOLET roller shutters and are available in a wide range of colours and finishes.

- Wood veneer-mesmerizing wooden patterns: Wood has many varieties: walnut, maple, beech, ash, etc. each corresponding to a particular shade. This range is also available in wood veneer edgebands.

- V-twin dual tone: A particular highlight within the V-twin is the stepped edge band with a groove. Whilst the upper section of the edgeband is available in typical glass colours, the lower section features aluminium.

|

If you want to buy REHAU edgebands for both commercial and residential projects at Wholesale Prices, visit the link below:

For more details, contact below:

|

Edgebanding tapes serve as one of the important components in modern furniture manufacturing, providing both functionality and aesthetic advantages. They protect the exposed edges from wear, moisture, and damage, thereby enhancing furniture durability and longevity. Easy to install and maintain, they improve the quality and visual appeal of furniture while being cost-effective. Being a key element, they make sure the furniture remains durable, attractive, and ready for everyday use.

FAQs

What thickness options are available for edgbanding tapes?

The thickness of edgebands may offer up to a number of options, usually from 0.4 mm to 2 mm. The most common thicknesses are 0.8 mm, 1 mm, and 1.5 mm, depending on the application and material. Edge bands come in several thicknesses, the thicker ones are for strength while the thinner ones are lighter and more flexible.

How do I maintain edge banding tapes?

To maintain edgebands, regularly clean them with a soft cloth and mild detergent to remove dust and stains. Do not use abrasive cleaners that will damage the surface. To preserve the edges from getting scratched, keep overly sharp items or force at the edges to a minimum. If the edges start to peel, reapply the adhesive or replace the band as needed for a fresh look.

Do edge banding tapes affect furniture durability?

Edge banding protects the exposed edges of panels from moisture, wear, and damage, preventing chipping and deterioration. Properly applied edgebands also help maintain the structural integrity of furniture, enhancing its lifespan while improving its overall aesthetic and functionality.

*The featured image used in this article is from ledgeband.com

REHAU uPVC edgeband: Transforming design norms, edge by edge

As our rapidly evolving world demands greater convenience and quality, the furniture industry is witnessing a significant tra