By normal definitions and understanding, check valves are intended to allow the flow only in one direction and not allow reverse flows. Check valves are generally installed in pipelines to prevent back-flow. A check valve is basically a one-way valve, in which the fluid ( liquid or gas) flow can run freely one way, but if the flow turns the valve will close to protect the piping, other valves, pumps etc. Another term commonly used for check valves is Non Return Valve (NRV).

Check Valves are self-automated valves that do not require assistance to open and close. They are found in any and every facility where a pump is installed for use. In fact, they are even found in homes where there is a sump pump in the basement or one at ground levels to fill an overhead tank – a check valve is installed in the discharge line of the pump.

Like many other valves, check valves find usage with a variety of fluids – liquids, air, other gases, steam, condensate, and in some cases, liquids with fines or slurries. The broad-based industry usage areas include pump and compressor discharge, header lines, vacuum breakers, steam lines, condensate lines, chemical feed pumps, cooling towers, nitrogen purge lines, boilers, HVAC systems, utilities, pressure pumps, sump pumps, wash-down stations, injection lines and hydraulic systems.

Common types of Check valves are the following :

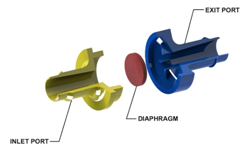

Diaphragm check valves employ a flexing rubber diaphragm positioned to create a normally-closed valve. Pressure on the upstream side must be greater than the pressure on the downstream side by a certain amount, known as the pressure differential, for the check valve to open allowing flow. Once positive pressure stops, the diaphragm automatically flexes back to its original closed position.

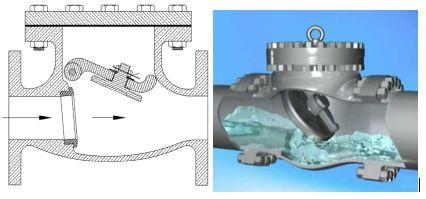

Swing Type Check Valve – Swing check valves feature a simple design complete with a disc attached to a hinge at the top. As fluid passes through, the valve remains open. When a reverse flow occurs, the changes in motion and gravity help to bring down the disc, effectively closing the valve. Swing check design is one of the most common and best check valve for general-purpose use. Pressure drop across the valve is low and the valve is conducive to low flow velocities and has the flexibility of horizontal or vertical pipe installations. Swing Check valves are not fast closing valves due to their design which allows a long travel distance for the disc from fully open to fully closed positions.

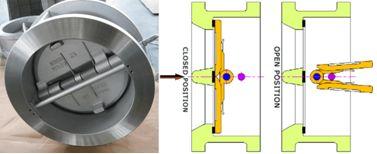

Split Disc Check Valve – Also referred to as dual plate check valve, it operates with a door that is split down the middle and only folds one way to regulate flow. When fluid enters the valve, the pressure causes the hinges of the door to open. When flow is stopped the door is shut.

The half circle discs are spring loaded and this enables them to close fast and significantly reduce water hammer. They are lighter and close fast due to the discs having to travel much lesser distance to close and is well suited for vertical pipe installations, hence making them one of the most efficient designs.

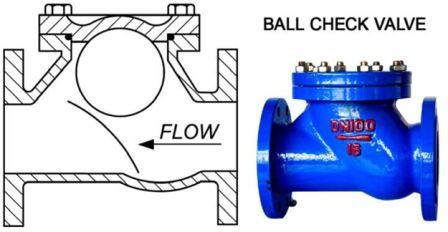

Ball Check Valves – Ball check valves use a spherical ball inside their bodies to help control the flow direction in pipes and systems. If pressure decreases or reverse flow is detected, the ball will move toward the seat. This creates a seal and helps to maintain the appropriate direction of fluid flow. In some ball check valves, the ball is spring-loaded to help keep it shut. For those designs without a spring, reverse flow is required to move the ball toward the seat and create a seal. The interior surface of the main seats of ball check valves are more or less conically-tapered to guide the ball into the seat and form a positive seal when stopping reverse flow.

The Incidence of Water Hammer*

Water hammer is a shock wave transmitted through fluid contained in a piping system. The most basic explanation is that water hammer occurs when a fluid in motion is suddenly forced to stop moving. The momentum of the fluid abruptly stopping creates a pressure wave that travels through the media within the pipe system, subjecting everything in that closed system to significant forces.

*Also read: Water Hammering In Piping Systems And Water Hammer Arrestors

The check valve essentially works to prevent reverse flow and hence if a pump stops and the forward flow reverses back down the line towards the pump before the check valve has fully closed, the flow will force the valve door to slam onto its seat. It is this fast closure and instantaneous stoppage which results in pipeline water hammer. Water hammer is evidenced by a thumping or banging sound that, in extreme cases, can cause extensive and costly damage to equipment like expansion joints, pressure sensors, flow meters and even pipe walls.

The consequent pressure wave (surge) can cause considerable damage to the system including pipe cracks, bursts, cavitation and implosion due to vacuum pressures being formed. It is also important to note that these failures may not be due to one single, large surge pressure but by repeated surges which eventually cause fatigue failure of the system.

Prevention of water hammer and stopping reverse flow are the two main criteria that need to be balanced for an efficient check valve.

Silent Check Valve are engineered to control and protect against pressure surges and thus prevent both water hammer and reverse flow . The differential pressure between the inlet and outlet of the valve is used effectively to initiate the closure of the valve ahead of the occurrence of the reverse flow. When the source moving the fluid shuts down and the forward flow of the fluid decreases, the specially designed stainless steel spring action of the silent check valve controls the valve disc closure to occur prior to flow reversal.

Silent check valves are constructed with a spring-assisted disc and this ensures that the valve does not slam shut, and the occurrence of water hammer is eliminated.

Selection Criteria – The factors important to the selection of check valves are:

(a) Head Loss – the cracking pressure or further the Flow Coefficient which is the Qty of fluid that will pass at a pressure differential of 1 psi effectively defining the efficiency of the valve is the key. Evaluation of friction resistance is another parameter.

(b) Fluid Compatibility – for example not all types of check valves can be used for say, waste water or water with sediments.

(c) Non Slam characteristics – this essentially considers the deceleration of the forward flow as well as the orientation of the valve particularly in vertical flow up piping systems where the vertical fluid column reverses much more rapidly, and of course,

(d) Costs – these shall include procurement, maintenance and energy costs .

Special configurations to avoid contamination particularly in potable water supplies– While Check Valves/ Non Return Valves are all expected to prevent reverse flow or backflow, there are some situations which require very stringent sealing characteristics in case of reverse flow. A typical example of this would be situations where potable water supplies are needed to be protected from contamination from other sources to which they may be connected. This is largely due to the requirement of provisioning cross connections. Some examples of cross-connections are fire sprinkler and irrigation systems, or hard pipe connections to equipment that uses water, such as beverage machines and dialysis equipment. Other cross-connections can be temporary, such as jumper connections, removable sections, swivel or change-over devices. An example of this would be the Fire Protection System which may also be connected to the water main as also to the outlet from the Tertiary Treatment Section of the Water Purification Plant. Or using sea water for fire control while also having fresh water as a back up whereby the need for protection of contamination of sea water into the fresh water system.

These systems employ in most cases double check valves to ensure prevention of reverse flow and may include detector assemblies for checking leakages. Such equipment are :

Double Check Valve Assemblies – Designed for use in non-health hazard cross-connections and continuous pressure applications subject to backpressure or back-siphonage incidents, such as lawn sprinklers, fire sprinkler lines, commercial pools, tanks and vats, and food cookers.

It consists of two check valves assembled in series and works on the principle that while one check valve will still act, even if the other is jammed wide open as also that the closure of one valve reduces the pressure differential across the other, allowing a more reliable seal and avoiding even minor leakage. Isolation valves like ball valves or gate valves on both upstream and downstream sides may be used for purposes of isolation and testing.

Reduced Pressure Zone Assemblies

These are designed for use in health hazard cross-connections and continuous pressure applications subject to backpressure or back-siphon incidents, such as containment at the main service line entrance, commercial boilers, hospital and laboratory equipment, waste digesters, and car washes.

There are two independent check valves installed in series, with a pressure monitored chamber in between which is maintained at a pressure that is lower than the water supply pressure, but high enough to be useful downstream. The device is equipped with a differential pressure relief valve which maintains the pressure and automatically relieves excess pressure in the chamber by discharging to a drain. Discharge from the relief device is an indication that either of the two check valves is ‘passing’ (leaking past their shutoff seats) or the relief valve itself is faulty.

Mr. Gautam Ghosal is the Director, Pansophical Technological Solutions Pvt. Ltd., New Delhi. He represents Watts Water – USA, Heinrich Schulte – Germany, Schloesser Armaturen – Germany and Arca Concepts – Italy. He can be reached on gg@pansophicalsolutions.com