All Epoxy floor coatings remain widely employed in the commercial and industrial flooring industries. Epoxy coatings remain typically placed on concrete floors to create a high-performance, smooth, and durable surface. Also, these surfaces can bear severe loads for many years. Epoxy flooring resin paint remains used in many industrial sites. Some examples remain warehouses and commercial buildings to keep workers, equipment, and inventory clean and safe. Also, epoxy floor resin, paint, and coating come in a wide cost range.

Epoxy floors application

We put epoxy over new concrete, cut epoxy is a great option to go over old concrete and make it look new. Because epoxy has colour in it, it doesn’t matter if the concrete is old and has stains on it, as long as you clean it really well, the epoxy will stick very well to the concrete and give you an amazing look. Epoxy doesn’t remain limited to solid colours, you can also do metallic epoxy floors. These metallic floors use metallic flakes to give you amazing variations in colours and make them look amazing.

Many people do metallic epoxy floors in their garages to enhance the look and give them a showroom look. You can also put epoxy over wood. If you have a countertop, you can seal the wood with APF P250 first, then put epoxy over it, and come back with a food-grade clear coat to make it food safe. Epoxy has tons of different uses, not limited to concrete.

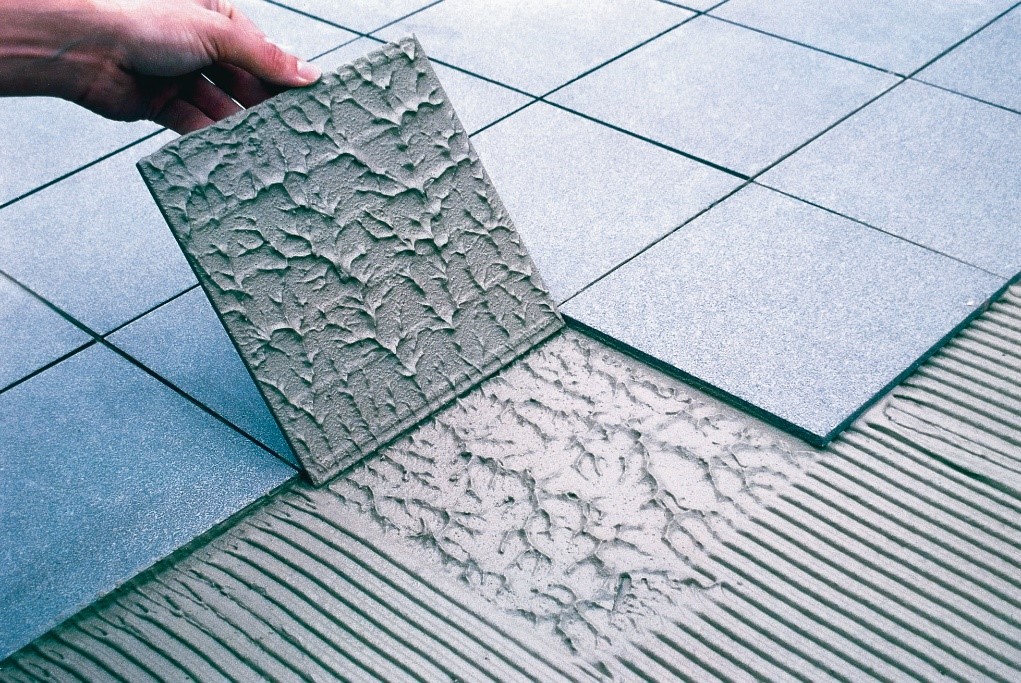

To adhere correctly, an epoxy coating requires a clean, slightly porous surface. The epoxy may not adhere to polished or sealed concrete. The concrete must also be completely cured. It is necessary to patch and repair all major cracks and chips in the concrete surface, as well as to remove all grease, before applying epoxy floor coating.

Test the surface for prior coats of epoxy or other compounds that may have remained applied over the years if the concrete is old. Pour a tiny amount of water onto the epoxy floor to check for sealant. It should take some time to sink in. If water beads on the surface instead of soaking in, the surface has most likely remained sealed and n longer remains suitable for an epoxy coating.

Image Source: Pinterest

Things to keep in mind

Make sure the temperature is appropriate before applying an epoxy coating, and follow all manufacturer’s instructions. Temperatures that are too hot or too cold can cause the epoxy to bubble and peel. Epoxy remains a two-part liquid that one must mix before use. Once you mix the epoxy coating, you only have a certain amount of time to apply it before it hardens. Thus, get the best epoxy floor for your surface at the best cost.