In building construction, plumbing pipes are designed to transport treated drinking water/potable water to end-users or consumers. These, aided by pipe fittings like steel, copper, and PVC pipe fittings, can serve different purposes such as water supply, drainage, waste disposal, etc. in a pipeline of different sizes of pipes.

Therefore, it is right to say that piping systems are designed in such a way that these primary purposes are served:-

- Supply water everywhere in the building

- Disposal of rainwater above the ground

- Disposal of water from drains, etc.

- Drain soil and wastewater to town sewers

It is a tubular or hollow cylinder used to convey fluids such as water from one place to another. It can also be used for structural applications.

Pipes usually differ depending upon their sizes:-

- With a large diameter that supplies water to towns

- Smaller branch lines that supply water to a street or group of buildings

- With a small diameter that supplies water within individual buildings

In every building, an adequate amount of water should be available at required places to meet the needs and demands of occupants. The transmission of water is done with the help of piping systems within the structure above or below the ground.

As builders and architects, it is of utmost importance to understand the pros and cons of the different types available in the market and then make an informed choice.

Contents

- 1 Types of pipes

- 2 Piping system

- 3 Pipe fittings

- 4 Standards as well as dimensions

- 5 Guidelines for stacking and storage of pipes

- 6 Identification of pipes by color

- 7 Maintenance of pipes and fittings

- 8 Top pipe manufacturers in India

- 9 Conclusion

Types of pipes

Stainless steel pipe

Image Source: masternet.com

It is one of the strongest and most durable variants available. They are capable of withstanding the high pressure of water and provide ease of usage. Available in comparatively longer lengths, it incurs low installation costs.

Having a high price point, these promise a high level of quality. Moreover, pipes are available in both flexible and rigid versions and in a variety of sizes.

Stainless steel pipes are used to carry fluids from one place to another under pressure. These are made from steel sheets, are lightweight, and can be bent easily.

| Also see: With sensor-controlled fittings, Schell is promoting sustainable plumbing in India: Ms. Andrea Bussmann |

Advantages

- Corrosion-resistant.

- Light in weight and have a higher flow rate.

- Unlike plastic, steel is 100 % recyclable.

- Have a long lifespan.

Disadvantages

- Have poor thermal conductivity.

- Not only expensive but also difficult to fabricate.

Applications

- Fertilizer industry

- Sewerage systems

- Casing pipeline

- Pipelines for natural gas

| Also see: SCHELL is India’s most affordable German plumbing brand: Mr. C. V. Dilipkumar |

Copper pipe

Image Source: Freepik

Copper is one of the most traditional materials used to manufacture plumbing pipelines. It remains a popular choice even today. Used in a plumbing system, these are of two types:-

- Rigid copper: It is used all over a house or building for the supply of water. It is also referred to as hard copper.

- Flexible copper: It is used in areas where space is tight and flexibility is required. It is a malleable option and therefore, is referred to as soft copper.

Advantages

- Have high corrosive resistance.

- Being sturdy, these are not prone to leakage.

- If these are to be replaced, the material can be recycled.

- Copper is capable of tolerating extreme temperature changes, including hot and cold water.

Disadvantages

- The main drawback of using them is their cost.

- Although recyclable, they cannot be considered a “green” product.

Applications

- Domestic water supply

- Air conditioning and refrigeration

- Fuel gas and medical gas

- Fire sprinklers

Galvanized Iron (GI) pipe

Image Source: Global Turk Trade

GI or Galvanized Iron pipes are made of mild steel sheets coated in a layer of zinc to prevent rusting. These are used to supply water, gas, or any other liquid inside the building.

These are prepared from 12 mm or 0.5 inches to 15 cm or 6 inches in diameter. They are available in 6 meters or 20 feet length.

Their ends are threaded so they can be screwed into each other.

Advantages

- Offering impeccable strength, these manage to resist rust for a long time.

- Have a low installation and maintenance cost. Therefore, these are very economical.

- Last around 20 to 50 years before starting to break down.

Disadvantages

- Rust can build up on the inside of these over a period of time.

- If corrosion occurs, the presence of lead can make the water unsafe to drink.

- Although very sturdy, they are also extremely heavy making them difficult to work with.

Applications

- Firefighting installations

- Sewerage systems

- Water and gas line

- Plumbing systems

Cast iron pipe

Image Source: steeltube.co.in

These variants were very popular for drainage systems in the first half of the twentieth century. However, these can still be found in many places today.

These are susceptible to rust over time and come in different sizes, the smallest one being four inches.

It is made from pig iron and is typically 5 cm to 120 cm in diameter. The usual length of its section is 12 ft., but a length of 20 ft. can be easily achieved as well.

These are dipped in a bituminous compound for protection against corrosion and for enhanced hydraulic qualities.

These are available in various shapes, like L-shape, T-shape, I-shape, U-shaped, etc.

Advantages

- Suitable for handling the high pressure of water.

- Not only are these economical but also have high resistance to corrosion.

- Have very high durability.

- These reduce sound and are heat-resistant.

Disadvantages

- These are very heavy and hence, have a high transportation cost.

- Due to their heavy load, these are manufactured in smaller lengths.

Applications

- Underground infrastructure

- Gas pipeline

- Sewerage systems

- Water supply and distribution system

Concrete pipe

Image Source: Stock

It has a long product life and offers one of the best service lives out of any other materials. It is easy to join and install. However, alkaline water may quickly degrade thin sections of it.

The precast variant is available in sizes up to 72 inches in diameter, and sizes up to 180 inches have been made on special order.

These pipes are reinforced except in sizes less than 24 inches in diameter. For heavy drainage and to dispose off the water, a large diameter is used. Smaller diameters are used for small flows.

Advantages

- Steel reinforced concrete is suitable for carrying all types of water.

- Easy to install and have flexible joints.

- These can withstand backfill pressure.

- These are water-tight and durable.

Disadvantages

- They are heavy and therefore, have high transportation and installation costs.

- It is difficult to re-establish the inner and outer coating if it is damaged during repair work.

Applications

- Rainwater drainage

- Pressure and irrigation

- Pipeline jacking and micro-tunneling

- Transverse culverts

PPR pipe

Image Source: jydjx.com

Polypropylene or PPR pipe is straight, rigid, and cylindrical, commonly available in green or white color. This offers an outer diameter ranging from 20 mm to 110 mm.

Resulting from European technology, these are made out of Polypropylene Random Copolymer plastic. These have low thermal conductivity and are cost-effective as well.

Advantages

- Economical and environmentally friendly.

- Have a long service life.

- The inner surface is very smooth and has low to zero friction.

- Have high chemical endurance and are abrasion-resistant.

Disadvantages

- Special tools are required for their installation.

- It is not a popular material anymore.

Applications

- Residential cold and hot water systems

- Sanitary and pure water pipelines

- Hot water recycling system

- Industrial and agricultural pipelines

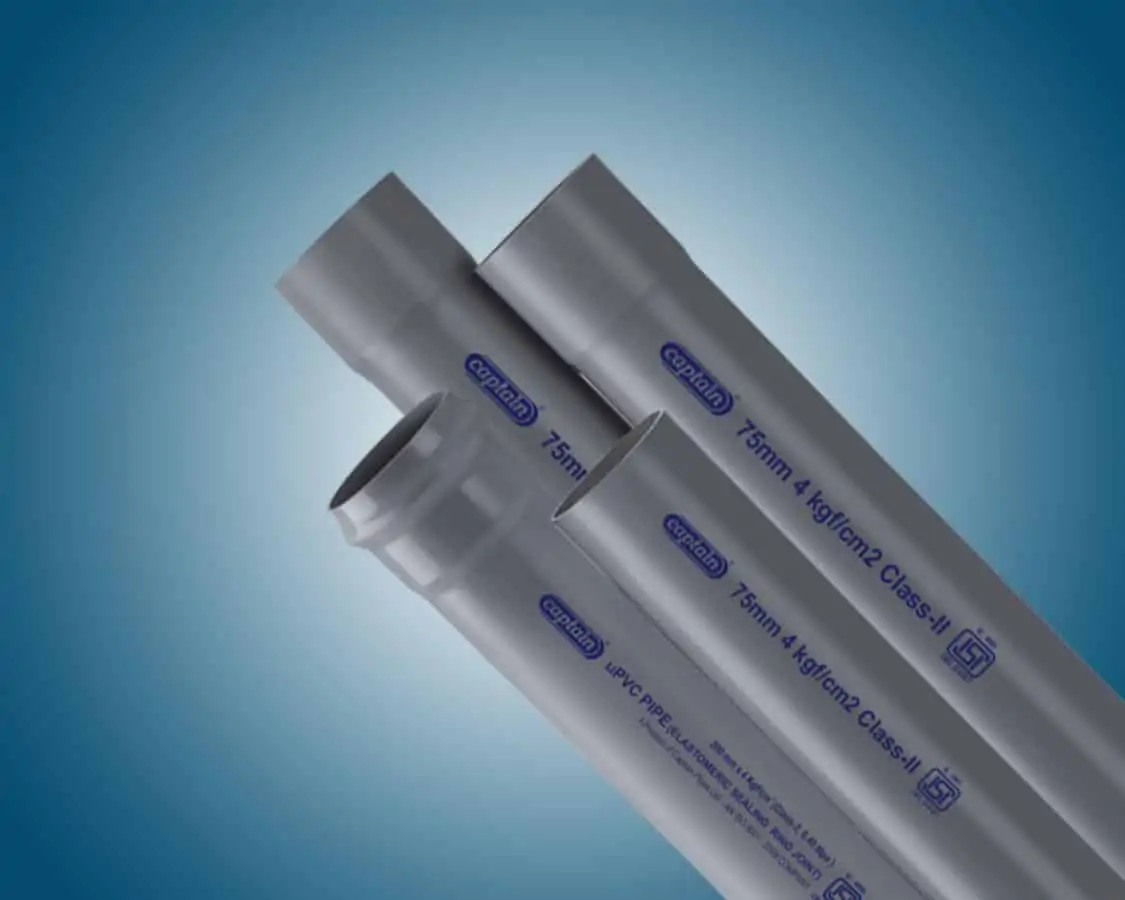

UPVC pipe

Image Source: captainpipes.com

Unplasticized Polyvinyl Chloride (UPVC), also referred to as rigid PVC pipe and fittings, are used for all plumbing purposes in residential and commercial buildings.

These are suitable for looping at each floor level, outdoor installations, and concealed lines for cold water distribution. The material, UPVC, has strong resistance to chemicals, sunlight, and oxidation from water.

Advantages

- Offer corrosion resistance since they are made out of plastic.

- Have a quicker installation time.

- Due to the strong material, these have a long service life.

- Their joints are leakproof.

Disadvantages

- Not recommended for hot water piping.

- This material may become brittle if exposed to sunlight for longer periods.

Applications

- Drinking-water distribution systems

- Sewer and discharge systems

- Electrical installations

- Water supply in irrigation

CPVC pipe

Image Source: FlowGuard Pipe and Fittings

Chlorinated Polyvinyl Chloride, abbreviated to CPVC, is closely related to PVC. Although both the materials are made from the same basic component, the main difference is that CPVC is chlorinated. This chemical difference gives CPVC the ability to withstand extreme temperatures, unlike PVC. Therefore, some building codes call for CPVC as a replacement for PVC to transport hot water.

it is a strong, durable plumbing solution and has found its applications all over the world for more than 50 years.

Originally developed by Lubrizol Advanced Materials, CPVC’s inherent chemical resistance and ability to withstand high heat and pressure make it suitable for residential, commercial, and industrial piping systems.

Advantages

- Made out of plastic material, these do not react to corrosive substances and do not rust as well.

- Have an indefinite lifespan.

- Having the ability to handle high water pressure, these are ideal for the main water supply line.

- CPVC is a lightweight material and hence, easy to move and work with.

- Can tolerate extreme temperatures up to 200 degrees Fahrenheit.

Disadvantages

- CPVC is ideal for indoor application only as it is vulnerable to breakage if exposed to sunlight for a long period of time.

- CPVC material costs more than PVC.

Applications

- Wastewater treatment system

- Drinking water supply system

- Metal industries

- Food and beverage processing industries

Piping system

A piping system is a network of pipes of different sizes arranged in a proper manner for the purpose of transfer of fluids. It is a collection of various components, fittings, and valves put together to perform a specific job.

The piping system in a building is largely governed by the type of building and how it has been planned. The system to be adopted is dependent upon the building and place of installation.

The piping system can be categorized into two, namely:-

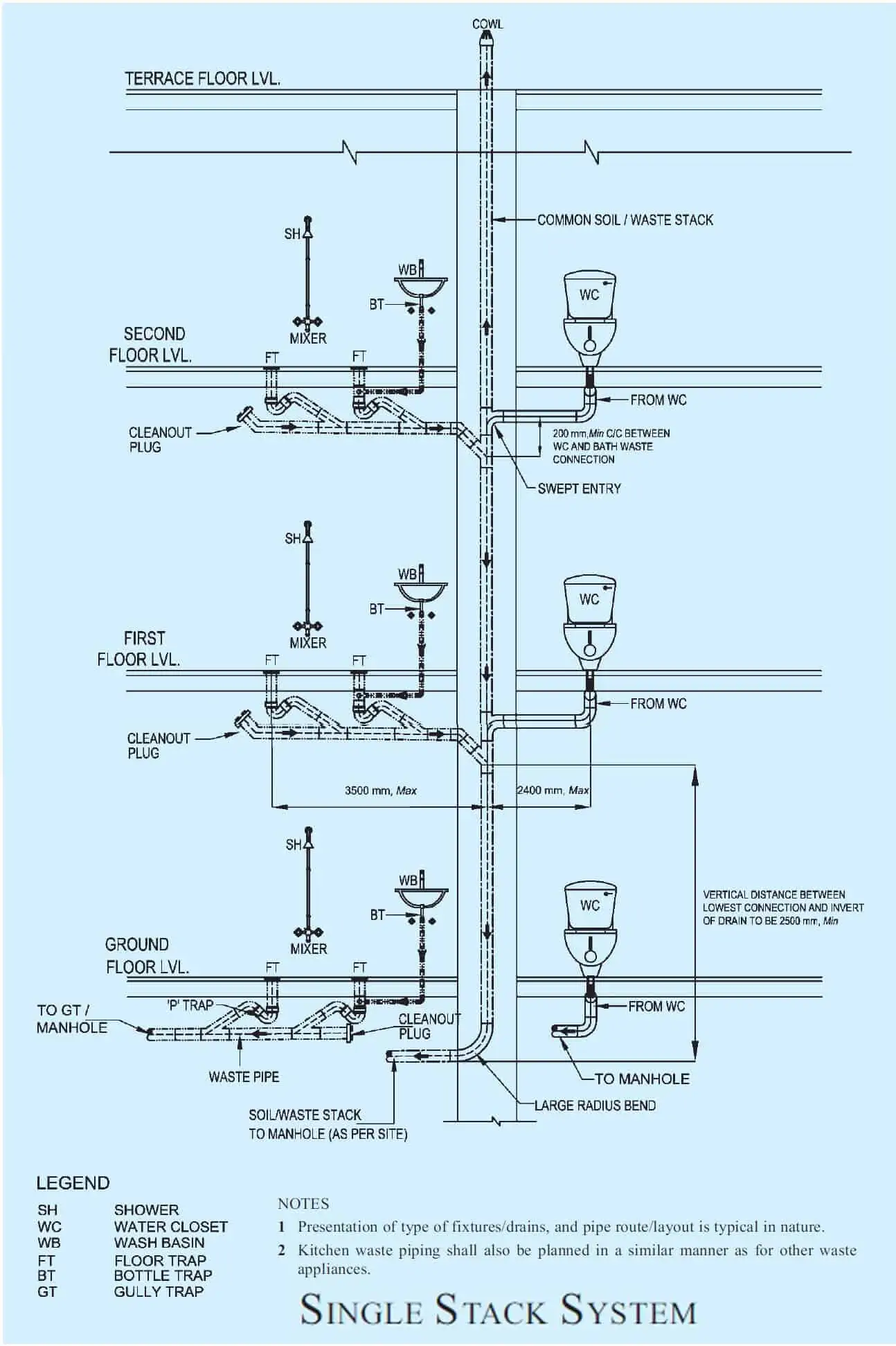

Single stack system

Image Source: archi-monarch

A single stack piping system has no particular trap ventilation as such. In this system, the stack itself acts as a vent through the roof.

Moreover, it is important to carefully measure the horizontal distance between sanitary fixtures and drainage stacks and the vertical distance between the connections of branches of both.

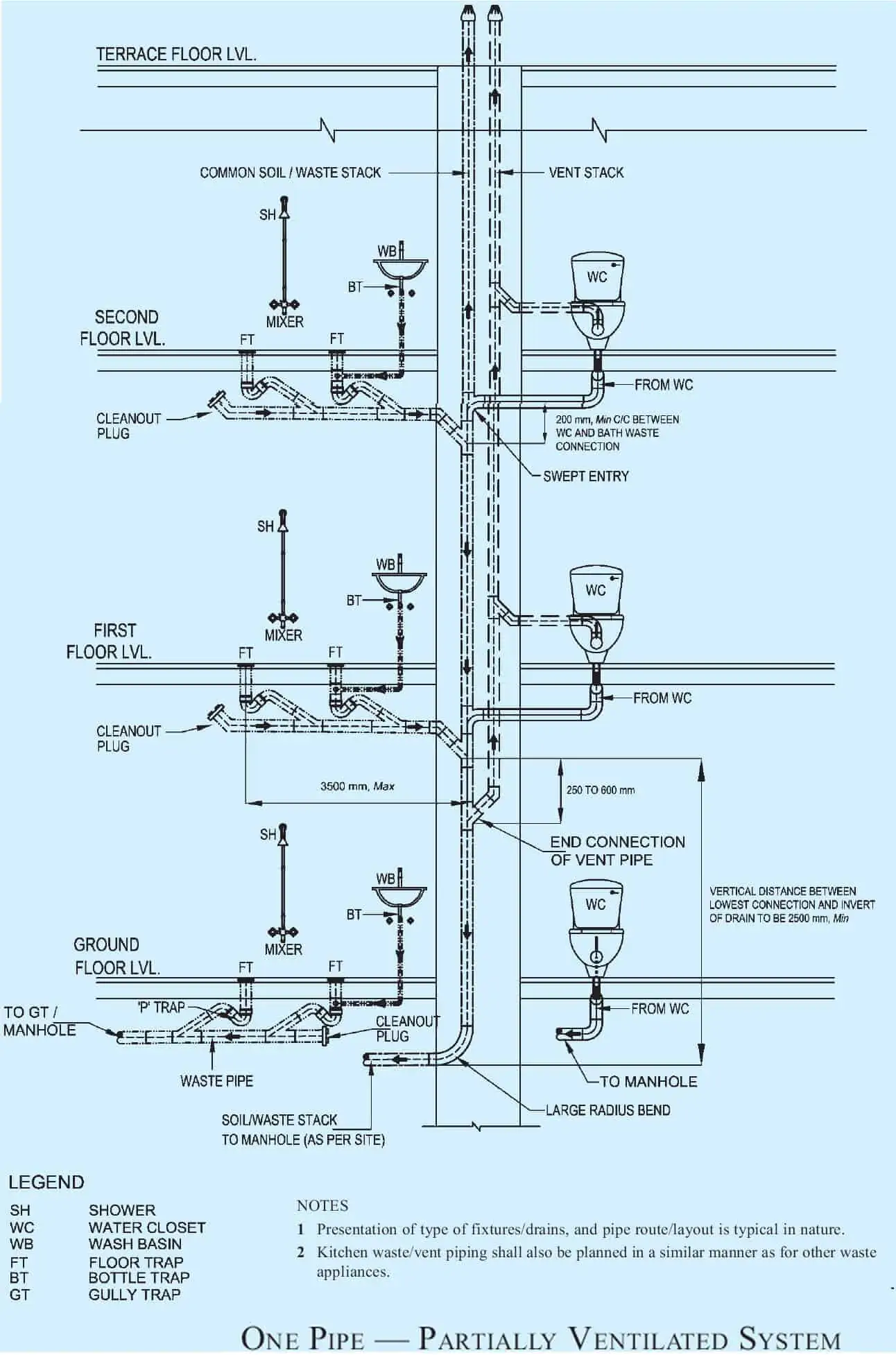

One pipe (partially ventilated) system

Image Source: archi-monarch

Also known as a single stack partially ventilated system, in this piping system, soil pipeline and waste pipeline are connected to a single vertical stack with an extra pipeline for ventilation.

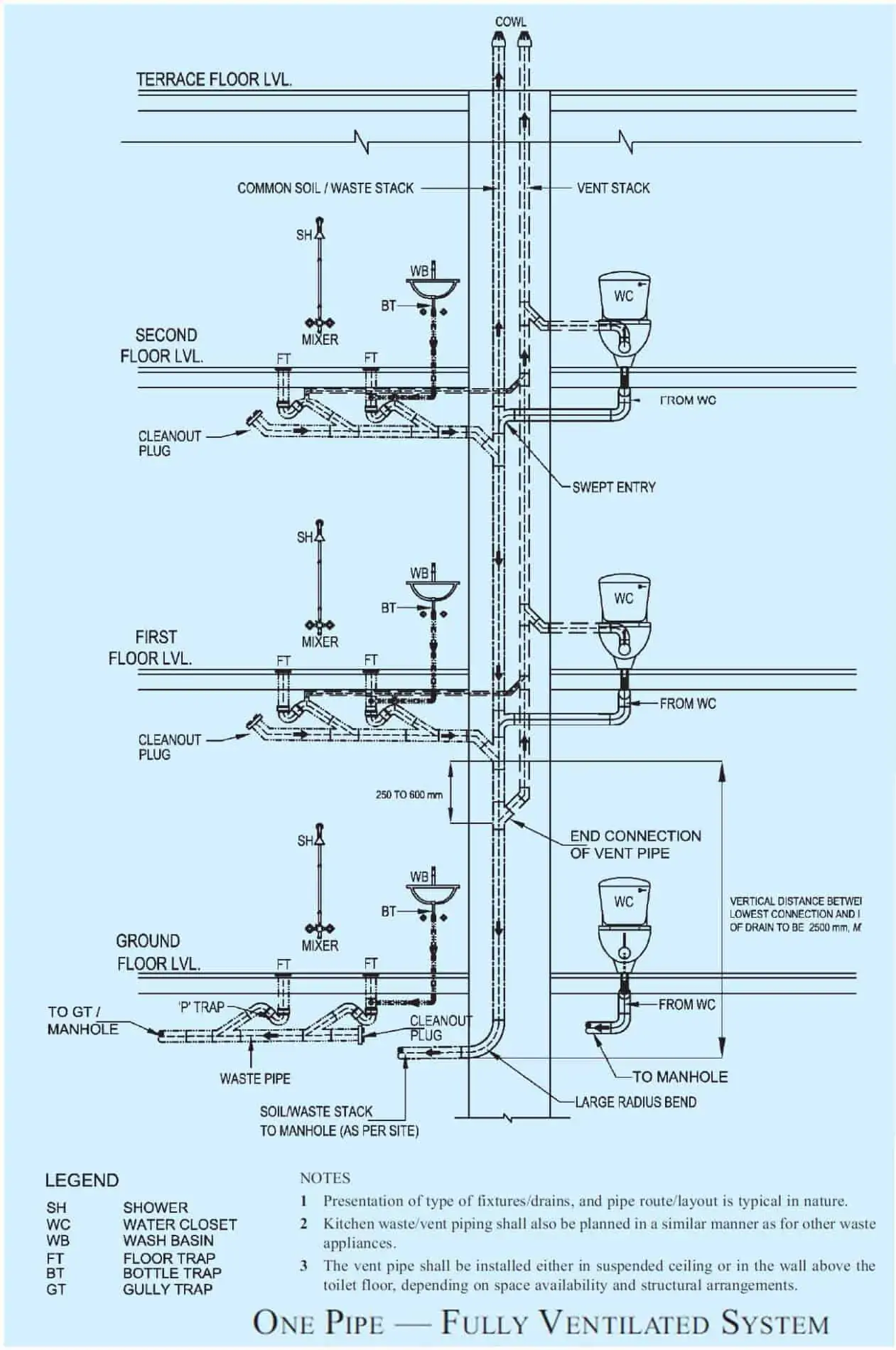

One pipe (fully ventilated) system

Image Source: archi-monarch

Also called the single stack fully ventilated system, in this piping system, the soil pipeline and waste pipeline are connected to a single vertical stack. Another trap pipeline is individually ventilated and connected to a separate stack.

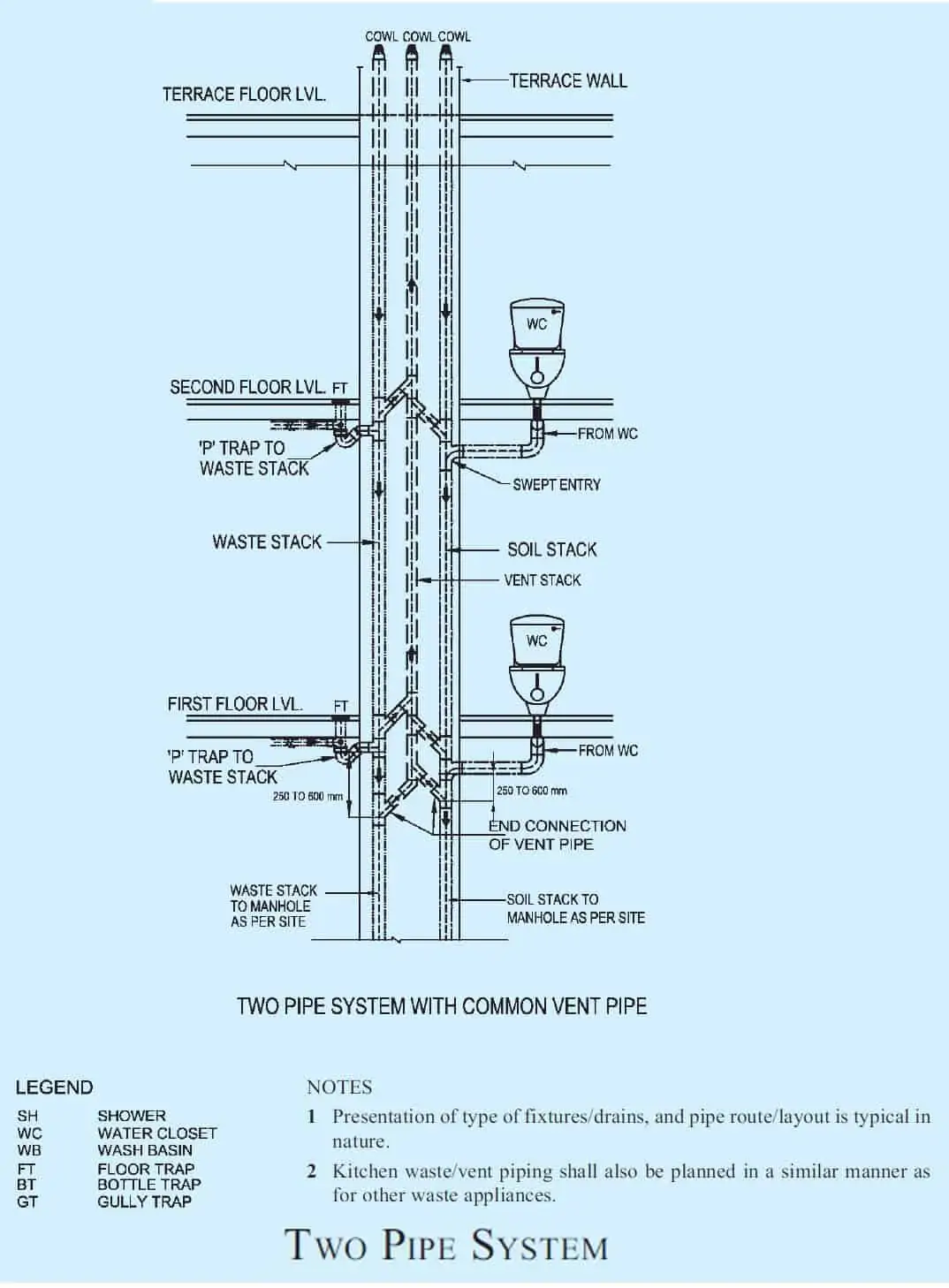

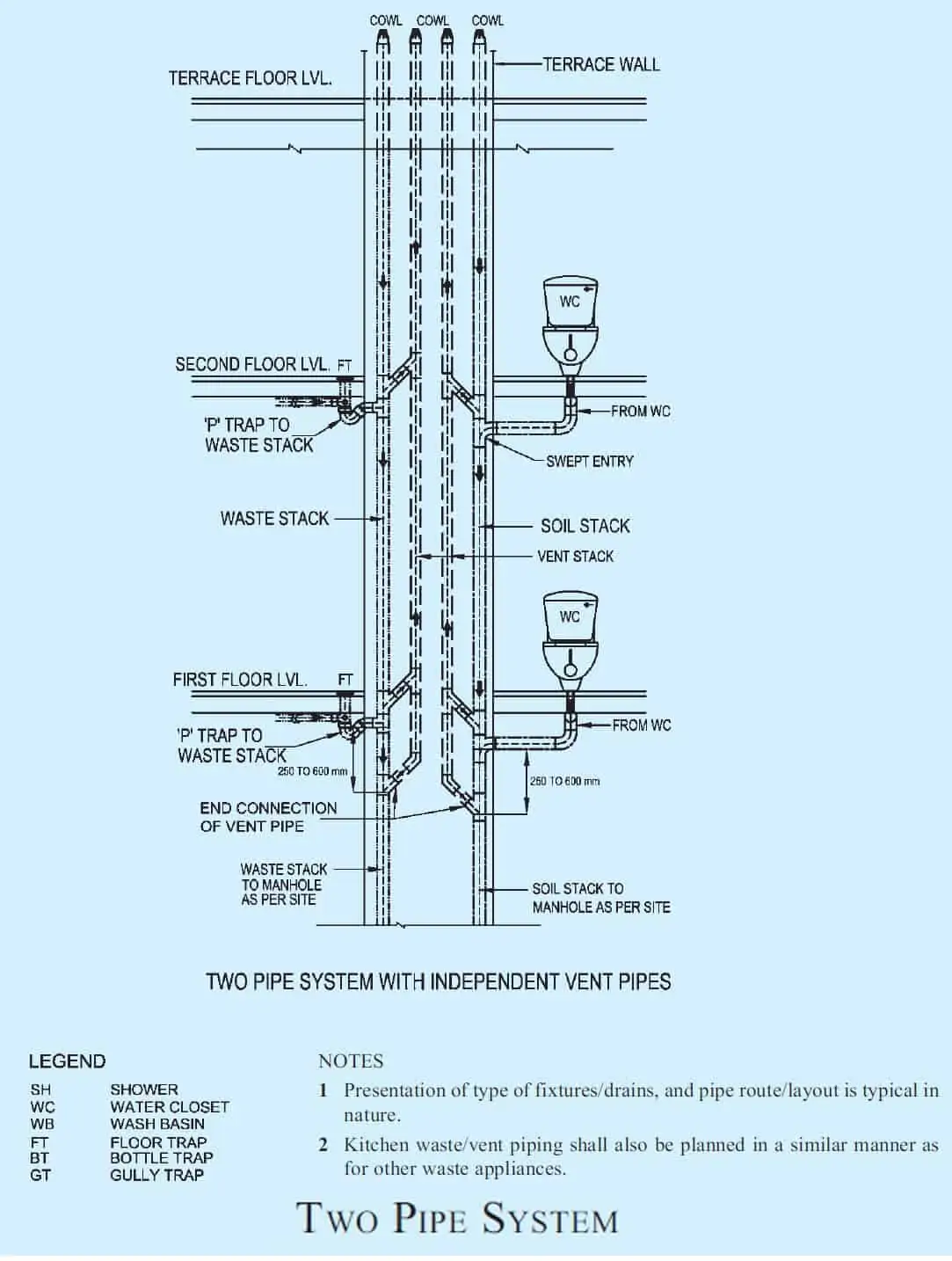

Two pipe system

In this system, all the soil appliances are connected to a soil stack and other plumbing fixtures.

Two pipe system with a common vent

Image Source: archi-monarch

In this piping system, there is a common vent stack for ventilation of soil and waste stacks.

Two pipe system with an independent vent

Image Source: archi-monarch

In this system, there are individual or independent vent stacks for the ventilation of soil and waste stacks.

Pipe fittings

These are used in piping systems for connecting straight sections, adapting to different shapes and sizes, and for regulating the flow of fluids or distributing them. These fittings are used in plumbing to manipulate the flow of materials within the piping system.

A pipe line system comprises other elements like fittings, joints, strainers, valves, bolts, flanges, gaskets, and supports as well in different sizes.

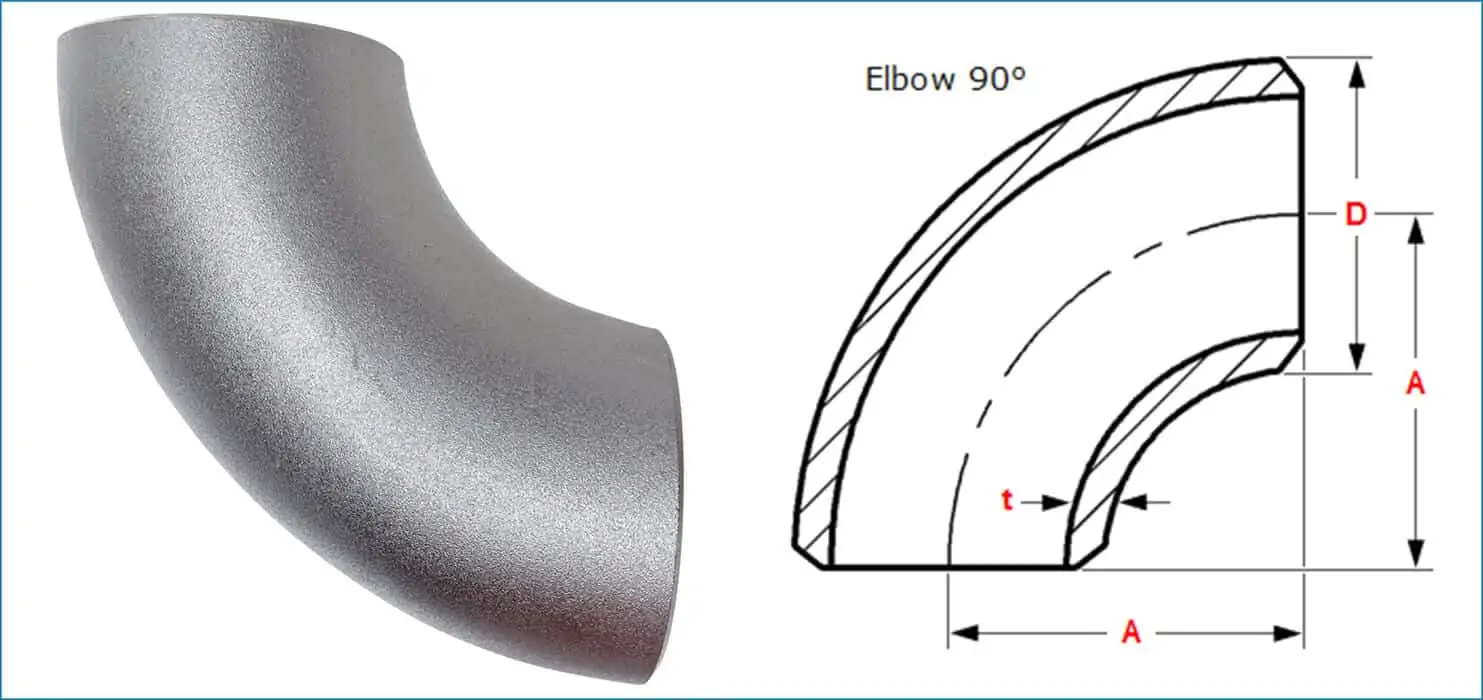

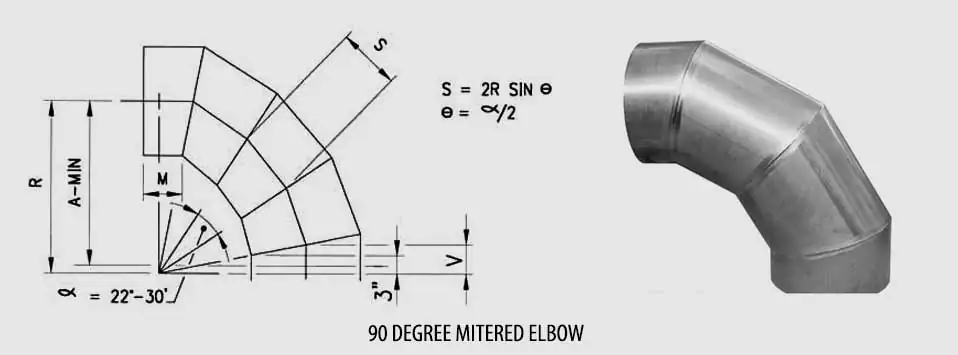

Elbows

Image Source: Neo Impex Stainless Pvt. Ltd.

Image Source: Kanak metal and alloys

Image Source: theprocesspiping.com

Elbows are used for the purpose of changing the angle or direction of the pipeline. These are most commonly found in 45-degree and 90-degree turns.

The bend in these fittings resembles an arm joint. These fittings can be made of different materials.

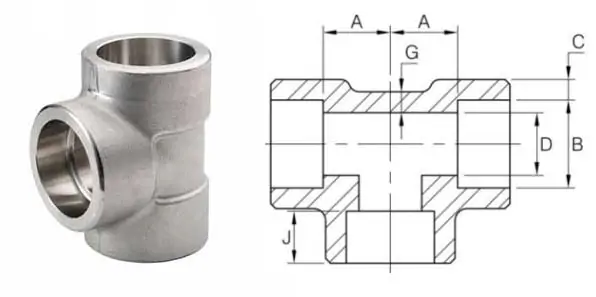

T-fittings or tee

Image Source: Haihao Pipe Fitting Factory

A tee, as the name suggests, resembles the letter ‘T’ and is the most common type of fitting. It is used to merge or divert the flow of fluids.

In addition, T-fittings can connect pipelines having different diameters or alter the direction of flow of fluids or both. These are made out of different materials and are available in various sizes and finishes.

Couplings

Image Source: Kompass

A coupling is yet another fitting used to make a branched connection. It serves the purpose of connecting.

There are two types of couplings, regular coupling, and slip/repair coupling.

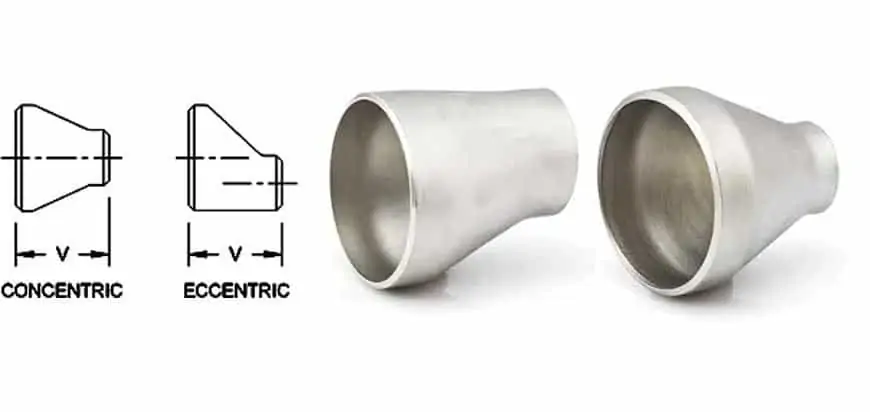

Reducers

Image Source: Star Tube Fittings

A reducer reduces the flow by sizing down the inner diameter. Therefore, the reducer may refer to any fitting which results in any alteration of the diameter. This change may be made to meet the flow requirements of the piping system or fit a different size.

Reducers are of two types:-

- Concentric: A reducer having a common centerline,

- Eccentric: A reducer having an offset centerline.

Bushings

Image Source: Pinterest

Bushings are used to make the diameter smaller in size. These fittings require very little application space and are capable of making abrupt changes.

There are two types of bushings:-

- Face bushings: The type that takes minimum space

- Hex bushings: The type that can be tightened with the help of a wrench.

Unions

Image Source: Pegler Yorkshire

Unions are similar to couplings in functionality. The main difference is that a union is more convenient and easy to use. Being easily removable, unions are a great option that offers easy maintenance and prevents the inconvenience of any future replacements. On the other hand, the coupling is a permanent fitting that can only be taken out by cutting it off.

A union contains three parts:-

- Nut

- Male end

- Female end

Caps

Image Source: Amazon

Pipe caps or caps are specialized fittings that are used to close any open end. These can be made out of rubber, plastic, or even metals.

Adaptor

Image Source: Fresh Water Systems

An adaptor is responsible for connecting two pipes that are not of the same size or material. Most commonly used for copper as well as PVC pipes, adaptors change a non-threaded end into male or female threads, as needed.

Following are some common types of adaptors:-

- Expansion adapters

- Mechanical joint (MJ) adapters

- Flange adapters

Plugs

Image Source: Ali Express

Generally used to close any opening, plugs are connectors that come in handy during the time of inspection or repairs. It can either be made out of metal, plastic, or rubber.

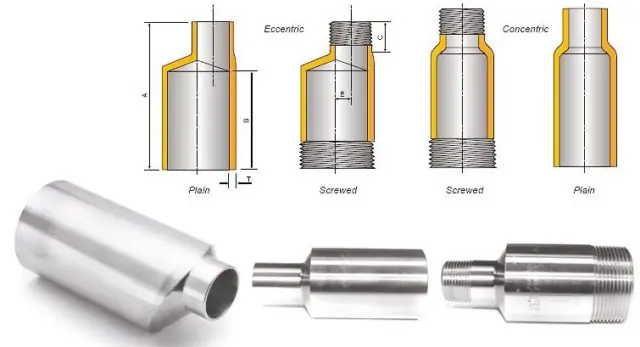

Swage nipple

Image Source: zzfittings.com

A swage nipple is similar to a reducer in functionality. The only major difference is that swage nipples generally connect a butt-welded pipeline to a screwed pipeline.

Similar to a reducer, these are also concentric as well as eccentric.

Following are the different end connections available in a swage nipple:-

- PBE: Plain Both Ends

- PLE: Plain Large Ends

- PSE: Plain Small Ends

- BLE: Beveled Large Ends

- TSE: Threaded Small Ends

Check valve

Image Source: Tameson

A check valve or a non-return valve is a fitting that allows the fluid to flow in one direction only. Thus, it has two openings in the body, one for fluid to enter and the other for fluid to exit the pipeline.

Majorly, these are of the following types:-

- Ball check valve

- Diaphragm check valve

- Swing check valve

- Stop-check valve as well as lift-check valve

- In-line check valve

Nozzle

Image Source: AliExpress

A nozzle is a device designed to regulate the direction as well as the properties of a fluid flow. Additionally, it is a fitting with a tube of assorted cross-sectional area. So, it is used to direct or manipulate the flow of fluids.

Thus, nozzles are often used to regulate the rate of flow, speed, direction, mass, shape, and pressure of the flow that surfaces from them. Moreover, in a nozzle, the velocity of a fluid increases with an increase in its pressure energy.

Globe valve

Image Source: exportersindia.com

Firstly, a globe valve is a fitting used in a case where frequent adjustment of the flow rate is required. It is a compression-type valve with a disk or a plug that is compressed into a seat to form a tight seal in its spherical body.

PVC fittings

Image Source: globalsources.com

Evidently, polyvinyl chloride or PVC pipe fittings connect two sections of a PVC pipeline together. Moreover, these come in a huge variety of configurations. They may be glued (S) as well as threaded (T).

Glued fittings are also known as slip fittings. While specifying a PVC pipe fitting, the size and type of connection are also required to be mentioned.

Copper tubing fittings

Image Source: exportersindia.com

Copper tubing uses compression fittings or a soft metal or thermoplastic ring. This ring is then squeezed into the pipeline.

So, these fittings adapt to the surface creating a seal. Thus, these are most commonly used in hot/cold water applications.

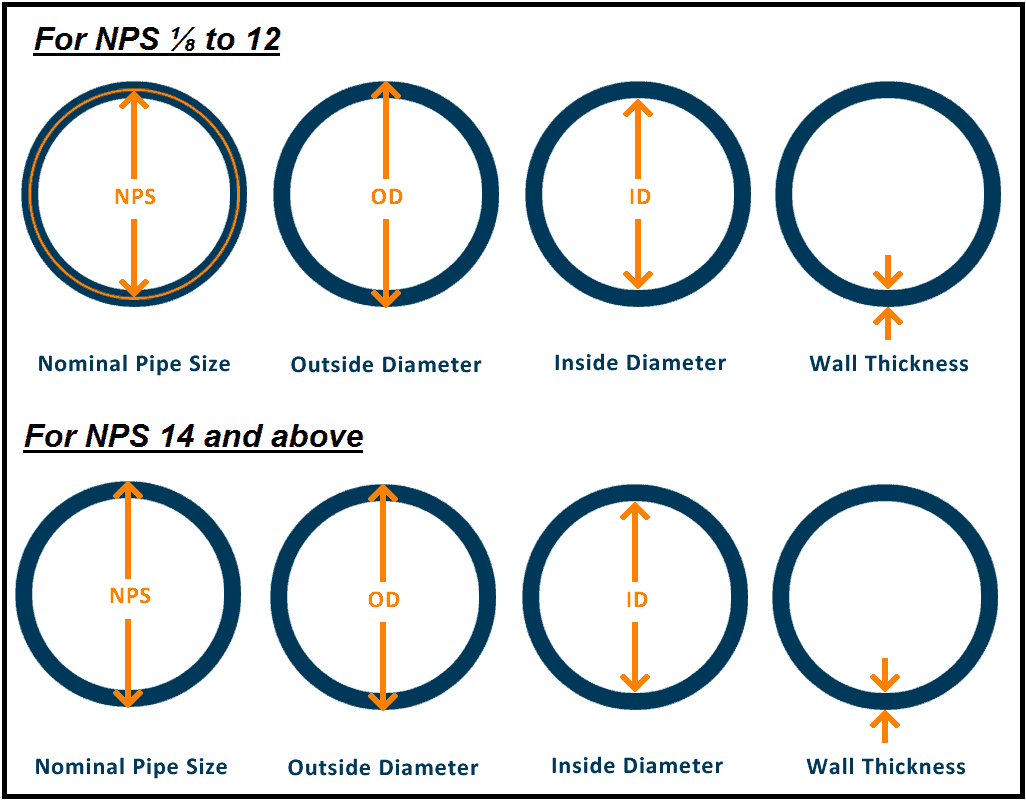

Standards as well as dimensions

For the purpose of sizing, each country has its own set of standards and codes.

The following table shows the major organizations for standards:-

| S.No. | Abbreviation | Organization | Country |

| 1 | ANSI | American National Standards Institute | United States |

| 2 | SCC | Standard Council of Canada | Canada |

| 3 | AFNOR | Association Francaise | France |

| 4 | BSI | British Standard Institute | United Kingdom |

| 5 | CEN | Committee of European Normalization | Europe |

| 6 | DIN | Deutsches Institute of Normung | Germany |

| 7 | JISC | Japanese Industrial Standards Committee | Japan |

| 8 | BIS | Bureau of Indian Standards | India |

| 9 | ISO | International Organization for Standards | Worldwide |

These standards establish common grounds such as engineering criteria, principles, manufacturing process, practices, materials, etc. Moreover, they establish a standard way of working that minimizes mismatching.

In addition, a few other generally referred to standards are The American Petroleum Institute (API) Standards, The American Iron and Steel Institute (AISI) Standards, and The American Society of Mechanical Engineers (ASME) Standards.

The Bureau of Indian Standards (BIS), so far, has not developed any standards for the design. Therefore, ANSI and ASME are widely used for their design in India.

Image Source: theprocesspiping.com

Pipe Schedule 40

| Nominal pipe size [inches] | Outside diameter [inches] | Outside diameter [mm] | Wall thickness [inches] | Wall thickness [mm] | Weight [lb/ft] | Weight [kg/m] |

| 1/8 | 0.405 | 10.3 | 0.068 | 1.73 | 0.24 | 0.37 |

| 1/4 | 0.540 | 13.7 | 0.088 | 2.24 | 0.42 | 0.84 |

| 1/2 | 0.840 | 21.3 | 0.109 | 2.77 | 0.85 | 1.27 |

| 3/4 | 1.050 | 26.7 | 0.113 | 2.87 | 1.13 | 1.69 |

| 1 | 1.315 | 33.4 | 0.133 | 3.38 | 1.68 | 2.50 |

| 1 1/4 | 1.660 | 42.2 | 0.140 | 3.56 | 2.27 | 3.39 |

| 1 1/2 | 1.900 | 48.3 | 0.145 | 3.68 | 2.72 | 4.05 |

| 2 | 2.375 | 60.3 | 0.154 | 3.91 | 3.65 | 5.44 |

| 2 1/2 | 2.875 | 73.0 | 0.203 | 5.16 | 5.79 | 8.63 |

| 3 | 3.500 | 88.9 | 0.216 | 5.49 | 7.58 | 11.29 |

| 3 1/2 | 4.000 | 101.6 | 0.226 | 5.74 | 9.11 | 13.57 |

| 4 | 4.500 | 114.3 | 0.237 | 6.02 | 10.79 | 16.07 |

| 5 | 5.563 | 141.3 | 0.258 | 6.55 | 14.62 | 21.77 |

| 6 | 6.625 | 168.3 | 0.280 | 7.11 | 18.97 | 28.26 |

| 8 | 8.625 | 219.1 | 0.322 | 8.18 | 28.55 | 42.55 |

| 10 | 10.750 | 273.0 | 0.365 | 9.27 | 40.48 | 60.31 |

| 12 | 12.750 | 323.8 | 0.406 | 10.31 | 53.52 | 79.73 |

| 14 | 14 | 355.6 | 0.375 | 11.13 | 54.57 | 94.55 |

| 16 | 16 | 406.4 | 0.500 | 12.70 | 82.77 | 123.30 |

| 18 | 18 | 457.0 | 0.562 | 14.27 | 104.67 | 155.80 |

| 20 | 20 | 508.0 | 0.594 | 15.09 | 123.11 | 183.42 |

| 24 | 24 | 610.0 | 0.688 | 17.48 | 171.29 | 255.41 |

| 32 | 32 | 813.0 | 0.688 | 17.48 | 230.08 | 342.91 |

*Schedule 40 chart gives sizes of all types of pipes such as stainless steel, zinc-coated, PVC, galvanized iron, copper, and carbon and chrome pipes.

Guidelines for stacking and storage of pipes

In order to standardize the storage, handling, and stacking process, engineers, architects, and builders across the country follow certain specifications.

Stacking and storage of cast iron, galvanized iron, and asbestos cement pipes and fittings

- They should only be unloaded when there is a requirement for them. Moreover, before unloading, trenches to store them must be ready.

- Store these pipes on a clear, level as well as firm ground surfaces. Moreover, for the stability of the stack, wedges should provide additional support to the bottom layer.

- Then, the stack height shall not exceed 1.5 m. Moreover, it is advisable to store pipes in length-wise or cross-wise patterns or in a pyramid shape.

- In addition, each stack shall be marked with an identifiable batch number with particulars of suppliers and shall contain pipes belonging to the same class or size.

- Cover, stack, and store cast iron pipe as well as fittings separately from the asbestos pipe and fittings.

- Also, keep the rubber rings away from grease, oil, light, and heat in a clean environment.

Storage and stacking of polyethylene pipes

- Firstly, polyethylene pipes should be protected from direct sunlight. So, they must be stored under covers. However, black polyethylene pipes could be stored in the open or under covers, as required.

- In addition, keep the coils away from hot surfaces. So, stack them flat one on top of the other or on the edge.

- Also, store the straight lengths on horizontal racks with continuous support to avoid a permanent set.

- Moreover, avoid storage of these in heated areas exceeding 27-degree Celsius.

Stacking and storage of UPVC pipes

- Store UPVC pipes on a flat surface that is free from stones and sharp objects.

- For the purpose of storage, big sizes of pipe racks and stacking in large piles must be avoided.

- Do not store a UPVC pipe inside another PVC pipe.

- Also, never store a PVC pipe in a stressed or bent condition. Moreover, store them away from any type of heat source at all times.

- Moreover, the height of a stack should not exceed 1.5 m.

- Stack different classes as well as sizes of pipes separately.

- In addition, protect the ends from abrasion.

- Due to humidity in tropical conditions, store the UPVC pipes in shade. However, during cold weather, care should be exercised for handling them as they get brittle and prone to breakage.

- Then, if it somehow becomes kinked, the damaged portion should be cut out completely.

Identification of pipes by color

To indicate the class of its contents, each pipe shall be marked with the appropriate primary identification colour, such as:-

| Contents | Identification color |

| Water | Sea green |

| Steam | Silver grey |

| Air | Sky blue |

| Drainage as well as other waste | Black |

| Gases | Canary yellow |

| Oils | Light brown |

| Acids as well as alkalis | Dark violet |

| Fire installations | Fire red |

So, apply the color marking to the entire length of the pipe or as a band of color near the valves, junctions, walls, etc. In addition, the minimum width of the color band should be 25 mm.

Where, in the usual course of manufacture or to satisfy the requirements of any other Indian Standards, a pipe is painted to a required color, the identification color shall be applied after the pipe is fixed in position. In addition, display charts showing the colors for primary identification at points were needed for reference.

Maintenance of pipes and fittings

- Replace the worn-out pipe fittings from time to time before they become brittle, fragile, or lose their shape permanently.

- During preventive upkeep analysis, cracks on the walls and footings near the pipe anchors will indicate a defective layout with regard to thermal expansion.

- Check and prevent any vibrations as well as expansions caused by the process equipment from being carried onto pipelines connected to them.

- Check if any modification such as expansion or shifting of equipment is affecting the pipeline installation.

- Before and during its use ensure the strength of the pipe by hydrostatic testing.

- Also, to prevent corrosion, depending on the material of your pipe, you should use an anti-corrosive coating.

- Since high mineral content can shorten the lifespan of your water pipe by clogging it, invest in a whole-house water softener system.

Top pipe manufacturers in India

Supreme Pipes

Due to its cost-effective piping solutions, Supreme is a renowned market leader in India’s plastic industry. Moreover, their wide range of products caters to almost all types of application segments. So, right from above-the-ground to underground applications, Supreme pipes have everything in plastic piping products.

Astral Pipes

Established in 1996, Astral Pipes offers CPVC, PVC as well as Pex plumbing pipe and fittings for hot/cold water. Also, it is one of the most reputed PVC pipe manufacturing companies in India.

Finolex Pipes

It is a top-rated PVC pipe and fittings company in India. Finolex pipe and fittings are available in various sizes, pressure classes, and diameters making them suitable for a wide variety of applications in both agricultural as well as non-agricultural sectors including housing, industrial, and construction.

Ashirvad Pipes

The leader in the manufacture of PVC as well as CPVC piping systems, Ashirvad Pipes is ISO 9001:2008 certified and is a National Award-winning company. Also, it develops and manufactures UPVC riser/column pipe used in the erection of submersible borehole pumps up to the depth of 1,000 feet and more.

Jindal Pipes Limited

Jindal Pipes Ltd., India’s one of the best as well as largest manufacturers of ERW, black and galvanized steel pipes, and tubes, offers different pipe thicknesses from 2.00 mm to 9.50 mm having an Outer Diameter (OD) ranging from 1/2′ to 14′ NB. Moreover, their products conform to various national and international standards. Thus, incorporated for the manufacturing of steel pipes and tubes, this company has brought great development in its manufacturing process.

Apollo Pipes

Apollo Pipes is a company that relies on modern technology for the manufacture of PVC pipes. So, having an extensive range of products, Apollo Pipes offers CPVC pipes and fittings, UPVC pipes and fittings, SWR pipes and fittings, UGD pipes, pressure pipes and fittings, UPVC column pipes, UPVC casing pipes, HDPE pipes, sprinkler system, solvent cement, etc.

Ajay Pipes

Ajay Pipes is a company whose products reflect innovative technology as well as impeccable quality. Moreover, it offers CPVC pipe and fittings, UPVC pipe and fittings, SWR pipe and fittings, and UDS pipe and fittings with high strength & durability.

Dutron

This company offers the cheapest range of PVC pipes worldwide. Also, they provide PVC pipes for all residential and commercial projects. Dutron is a pioneer of PVC hose pipes in India and has also started manufacturing PVC braided hoses, flat delivery hoses, corrugated pipes, and plastic sheets.

Tata Pipes

Tata Pipes is one of the first brands of plumbing pipes in India. Also, these pipes mainly carry liquids and low-pressure gases. Tata Pipes have an average 360 GSM zinc coating, better than IS 1239 spec to provide corrosion protection to the pipes.

Viega

Due to its wide range of products covering the entire installation technology sector, Viega has advanced to become an internationally operating market leader. Ensuring German quality standards, Viega offers connectors as well as pipe fittings with press connections made of gunmetal and multi-layer pipes.

Conclusion

In the building and construction industry, piping systems and piping materials play a vital role in performing the task of conveying fluids. Type of fluid as well as the circumstances of conveying them influence the materials used for making a pipe. Also, fluids can be hazardous, corrosive, or flammable in nature. Thus, pipes made out of different types of materials carry different types of fluids.

Pipes come in different sizes. So, they can be divided into three main categories: metallic (galvanized iron, cast iron, steel, copper, etc.), cement (concrete cement, etc.), and plastic (UPVC pipes, CPVC pipes, etc.)

With this article, you would be now clear that CPVC is a higher grade of PVC pipes. In addition, it uses all the advantages of PVC and overcomes all the limitations of UPVC pipes.

Although a piping system not only involves different types of pipes, other components like fittings, valves, etc. remain equally important. Also, in plumbing, many types of fixtures join together as per requirement. Joints as well as fittings join straight pipes, change the direction of flow, or join pipes of different sizes.

Moreover, pipeline maintenance commences at the planning stages of your operation and continues throughout the life of your business. So, the best way to avoid issues in a pipe and keep energy costs down is to make sure that the piping system is working properly.

As a professional, it is your responsibility to ensure a smoothly operating as well as efficient piping system. For this, builders, architects as well as engineers across the country follow certain standards. Moreover, these comprehensive specifications provide instructions for pipe stacking, storage, and installation.