The difference between sealants and adhesives remains quite ambiguous. Often professionals find themselves in situations where they can’t decide which product to choose for a specific job. Also, these are used in several ways such as wallpaper and tiling adhesives, or silicone sealants.

These construction chemicals sometimes use the same material for their preparation. However, the processing time and composition differ in both. But these differences are not quite obvious. They determine the final results of using either of the products.

So, it becomes extremely important to understand the difference between these construction chemicals so that we can choose the perfect product for the perfect job.

Contents

- 1 Adhesives

- 2

- 3

- 4

- 5 Sealants

- 6

- 7

- 8

- 9

- 10 Difference between adhesives and sealants

- 11

- 12 Conclusion

- 13

Adhesives

What is adhesive?

Image Source: foreign policy

The meaning of adhesives: Adhesive is an umbrella term for substances that join, bind, hold, or fasten two or more materials together. Also, the cohesive and adhesive forces determine the strength of the adhesive tape, glue, or spray.

The cohesive force allows the force of attraction between two similar substances. On the other hand, the adhesive force attracts two dissimilar substances.

But the failure point of both cohesive and adhesive forces for each adhesive tape, glue or paste help determine the most appropriate type of adhesive in the particular application.

They are used for permanent, semi-permanent, and even temporary attachments. Also, they are used in various industrial and residential applications.

Advantages of adhesives:

Versatility: The adhesive force ensures the binding of different types of materials together. So, you can use the chemical for multiple purposes.

Simple application: These are generally applied mechanically. As a result, the process becomes quite cost-effective. You do not have to arrange many resources for its application. It can be done manually very easily.

What are the types of adhesives?

We get this chemical both, naturally and synthetically. Some of the common types used in building construction are:

Image Source: Food52

Polymer adhesives

This type has high impact resistance, more flexibility, and greater strength. Also, it is used in the construction, automotive, electronics, electricals, and aerospace industries.

Acrylic adhesives

This type of adhesive offers a high adhesive force bond for mechanical joining. Also, acrylics are used for many types of surfaces.

Resin adhesives

Use resin adhesives for superior bonding capabilities. Also, they come as adhesive sprays, emulsions, and other liquid forms. These chemicals are used with materials such as fabric, wood, metal, glass, etc.

NOTE: Epoxy resin does not have water-resistant properties. So, it should not be applied in moist and wet conditions.

Epoxy adhesives

The epoxy adhesives made from Epoxy resin have high strength. Also, they have high resistance to chemicals and creep under sustained load. So, epoxy adhesives are widely used as structural chemicals.

Hot melt adhesives

The hot melt chemicals are sold as the hot glue gun. Also, they have a long shelf life. So, they have better advantages over solvent-based chemicals.

Watch this video to understand all about hot melt chemicals:

Anaerobic adhesives

The anaerobic chemicals are less toxic and not corrosive to metals. Also, the structural bonds make use of anaerobic chemicals with materials like glass and metal.

Thermoset adhesives

These crosslinked polymeric resins are majorly used for structural load-bearing applications. They have the amazing gap-filling ability and come with moisture and heat-resistant properties.

Water-based adhesives

The water-based chemicals use both natural polymers and soluble synthetic polymers. Also, water must be mixed with these chemicals. These can be used as sprays and by wiping the glue with a wet roller or brush.

Pressure-sensitive adhesives

The pressure-sensitive chemicals remain in viscous form. Also, the strength of the pressure-sensitive chemicals decreases with an increase in the temperature. So, they are used in unbonded and bonded places such as filter frames, holding the components like gaskets, assembly of membrane switches, etc.

Cyanoacrylate adhesives

The cyanoacrylate chemicals offer high-temperature resistance and excellent metal and plastic bonding. Cyanoacrylate chemicals have low odour and impact resistance. Also, they are used for bonding materials and work best as adhesive for plastic, metal, silicone adhesive bonding, metal, rubber adhesive, and other substrates.

PVA adhesives

The PVA adhesive, also known as Polyvinyl Acetate is a water-soluble, non-toxic, non-acidic, adhesive suitable for porous materials. Also, this adhesive is an ideal adhesive for wood, and adhesive for wallpaper, etc.

Contact spray adhesive

The spray allows temporary and permanent bonding. Also, the spray can be used on uneven surfaces. The contact spray chemical does not stain and remains environmentally friendly. Some forms such as tapes and hot-melt chemicals are also used for purposes other than the hardcore construction industry.

What are the various applications of adhesives?

These can be used as one of construction chemicals in the following ways:

- Countertop lamination

- Carpet layering

- Flooring

- Drywall lamination

- Timber joining

- HVAC connections

- Pre-fabricated panels

- Roofing

- Wallcovering

- Sealants

- Binder in roads

Applications of popular adhesives products for flooring, wall, and ceiling

Adhesive tiles for floor and wall tiles

Image Source: flizuoutlet

Flooring is an integral part of any building. Also, it adds to the overall look and feel of the room. So, it becomes extremely important to ensure that your space has beautiful flooring.

Tiles are one of the most popularly used flooring materials. Also, the tile adhesive is used to fix tiles in the space.

These adhesives for floor tiles make use of ready-made mixtures of Portland cement, polymers, and some additives for the excellent laying of tiles.

Also, the adhesive for wall tiles comes with non-skid properties. So, these ready-to-use tiling adhesives for wall tiles make use of polymer.

The tiling adhesives for walls, floors, etc. settle on epoxy, cement, and polymer primarily.

- Acrylic tiling adhesive for floor tiles: These tile adhesives fix small-sized tiles such as vitrified tiles, ceramic tiles, natural stone tiles, etc.

- Epoxy tiling adhesive for floor tiles increases the hardness and strength. Also, epoxy tiling adhesive for floor tiles remains the strongest tile adhesive. It is mainly used in industrial applications.

- Latex tiling adhesive remains ideal for exterior use in places that require movement.

Watch this video to understand the correct application of tile adhesives:

Wallpaper adhesives- Self-adhesive wallpaper

Image Source: Alibaba

The best way to add a dramatic effect to your space would be by using ceiling adhesive wallpapers. Also, no other accessory can influence the vibe like wallpapers.

Additionally, self-adhesive wallpaper has become the new favourite of every interior designer. SO, the wallpaper adhesive makes it extremely time-efficient to stick the wallpaper.

The old-fashioned method of applying the wallpaper has become a thing of the past. But, modern wallpapers are non-toxic self-adhesive wallpapers.

0ther than ceiling wallpapers, you can use adhesive for wallpaper on the four walls of your room as well. Also, the adhesive wallpaper usually uses methylcellulose & starch, among other chemicals. So, the adhesive for wallpaper has increased viscosity and better application.

The self-adhesive wallpaper comes in many designs, surface textures, and patterns.

Watch this video to understand the correct application of self-adhesive wallpapers:

Popular adhesive manufacturers in India

- Fevicol (Pidilite Industries)

- Astral

- DuPont

- MYK Laticrete

- Sika

- BASF

- Asian Paints adhesive

- Fosroc

- 3m

Adhesives manufacturers in India (products and their prices)

| Sr. No. | Brand and Product | Price |

| 1. | MYK Laticrete LATAFIX Thin-set chemical | Rs. 300/20 kg bag |

| 2. | Sika Tilofix Tile chemical | Rs. 370/30 kg bag |

| 3. | BASF Master Tile chemical | Rs. 750/25 kg bag |

| 4. | Asian Paints Smartcare Tile on Tile chemical | Rs. 450/ 30 kg bag |

| 5. | Fosroc Nitotile Multi-Purpose Tile chemical | Rs. 370/ 30 kg bag |

| 6. | 3m Synthetic Resin chemical | Rs. 263/kg |

Sealants

What is a sealant?

Image Source: chemical wiki

Sealants meaning: The construction chemical- restricts fluids and other substances from passing through the mechanical joints and surfaces of a building. Also, it blocks dust, acoustics, air leakage, heat, and insects.

These come in a wide range of options. Their characteristics differ: rigid or flexible, strong or weak, and permanent or temporary. But, the main purpose of this construction chemical remains to close the openings between surfaces where mortar or concrete cannot be used.

Functions of sealants:

- Sealants fill the gap between the two materials/ surfaces/ components.

- They offer a protective barrier, through which no substance can pass.

- Also, the sealants ensure that the components retain their sealing properties throughout their lifetime.

Advantages of sealants:

- Consistency: Highly viscous construction chemicals do not flow much even on the vertical joints. Low viscosity sealants have the ability to penetrate deep inside the substance can become self-levelling.

- Weather-resistance: High performing construction chemicals withstand extreme temperature, moisture, and heat. So, they do not compromise their performance and flexibility.

- Movement: The viscous construction chemicals move enough to enter even the remotest area and level it perfectly.

- Durability: When applied properly, these construction chemicals last even longer than their expected life cycle.

- Adhesion: The sealants have a strong adhesive force. So, the adhesion in sealants remains an important factor while choosing them.

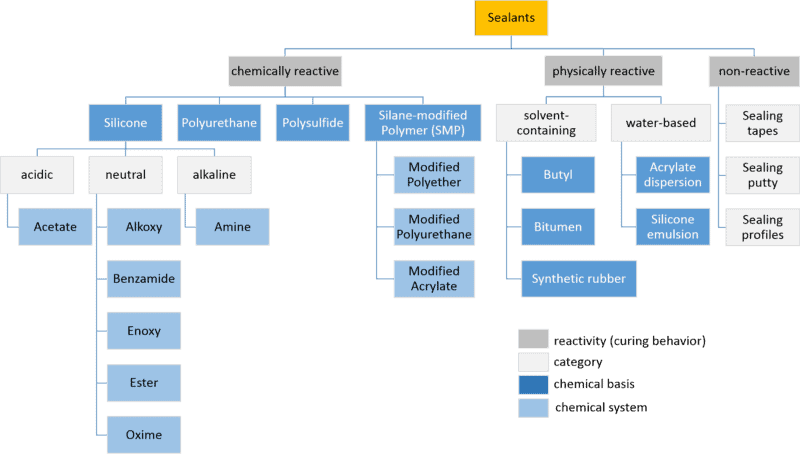

What are the types of sealants?

Image Source: Wikipedia

The most common types of sealants in construction chemicals differ in composition, materials, substrate, cost, and application.

Latex sealants

The latest sealants have water-based composition. Also, they remain easy to clean and adhere to most of the substrates. So, you can apply sealant paint on the latex sealants. These sealants come at a lower price than other sealants.

These latex sealants are applied at places with small gaps with minimal movement.

Acrylic sealants

The solvent-based acrylic sealants with UV stability come with paintable features. So, you can use sealant paint. They are not prone to shrinkage, unlike latex sealants. But, the application of acrylic sealants is more complicated than latex sealants.

They come with commercial and exterior applications.

Silicone sealants

The silicone sealants come with brilliant thermal resistance and good adhesion force. They have fine dynamic movement capability. Also, silicone sealants also have UV resistance and long service life. Silicone sealants have the highest movement capability and long service life.

But, silicone sealants are waterproofing sealants that have a strong odour and cannot be painted. So, you cannot use sealant paint here.

The glass silicone sealants are used in glass assemblies and for bonding metal to frames. So, they become ideal glass silicone sealants.

Watch this video to understand where NOT to use silicone sealants:

Butyl sealants

This solvent-based butyl sealants come with strong adhesion force to multiple substrates. Also, they have poor abrasion resistance and limited movement capability. So, they have a difficult application.

The butyl sealants are applied in curtain wall systems and where the need for adhesion to rubber material arises.

Polyurethane sealants

The durable polyurethane construction chemicals have high movement capability. But, their application and tooling remain complicated and expensive. Polyurethane sealants come with excellent shape retention and fast curing rates.

Also, polyurethane construction chemicals make use in plumbing, road repair, and construction. Polyurethane sealants or PU sealants are used in places that need high-strength and water-resistant sealants.

Polysulfide sealants

The polysulfide construction chemicals have excellent flexibility at low temperatures. Also, polysulfide construction chemicals have little shrinkage and no UV degradation. So, the polysulfide sealants have a life expectancy of 10-20 years. They are used in underwater applications.

Thread sealant

The thread chemical prevents leakage of gas and liquid on metal joints and pipes. So, thread chemicals make use of metal fitting surfaces.

Watch this video to understand more about this construction chemical and its uses in the construction and restoration industries:

What are the various applications of sealants?

These can be used in the following areas:

- Cement

- Roofing

- Sealants for roofs

- Glass sealants

- Sealants for wood

- Rubber sealants

- Wall sealants

- Sealants for concrete

- Door sealants

- Sealants for joints

- Gasket sealants

- Sealants for windows

- HVAC

- Architectural

- Asphalt

Popular sealants brands and products

- McCoy

- Astral Sealant

- Mapei

- ESSRBOND

- Fixit (Pidilite Industries)

- Asian Paints

- Dowsil

- Alstone

- Sika

- Roff (Pidilite Industries)

Sealant products and their prices

| Sr. No. | Product | Price |

| 1. | Mccoy Sealant McCoy Soudal WeatherSeal Black Silicone sealant | Rs. 274/ 350 gm |

| 2. | Astral General Purpose (GP) Silicone Sealant | Rs. 400/ 260 ml |

| 3. | Mapei Kerapoxy Design Tile Sealant | Rs 800/kg |

| 4. | ESSRBOND Modified Polymer Sealant | Rs. 381/600 ml |

| 5. | Dr Fixit (Pidilite Industries) Feviseal Acetoxy Silicone Sealant | Rs. 445/ 280 ml |

| 6. | Asian Paints: Smartcare Hybrid Pu Grey Sealant | Rs. 466/ 300 ml |

| 7. | Dowsil General Purpose (GP) Silicone Sealant | Rs. 182/ 280 ml |

| 8. | Alstone Architectural Weatherproofing Silicone Sealant | Rs. 4996/kg |

| 9. | Sika flex Polyurethane Sealant | Rs. 1562/ 450gm |

| 10. | Roff (Pidilite Industries) | Rs. 980/litre |

| 11. | Dowsil Industrial RTV GP silicone Sealant | Rs. 300/ 280 ml |

| 12. | McCoy Expandable PU Foam sealant spray | Rs. 551/ 750 ml |

Difference between adhesives and sealants

Image Source: cision news

These construction chemicals seem quite similar in use. But, they differ drastically.

Sealants lack a high adhesive force. Also, adhesives have higher strength and more complex chemical structures.

Let’s understand the difference between these construction chemicals through this table:

| Sr. No. | Adhesives | Sealants |

| 1. | They remain capable of holding two surfaces with high adhesive strength. | These attach surfaces by filling the space between them. |

| 2. | Also, these have a more durable and rigid application. | But, these have lower strength and more malleability. |

| 3. | They can be used only in minor places where sealants were originally demanded. | These can be used in more areas that primarily need adhesives. |

| 4. | Also, they have greater holding and bonding adhesion force. | These are excellent for water and airtight spaces. |

| 5. | They have lesser elongation and flexibility. | These construction chemicals have higher elongation and flexibility. |

| 6. | Also, these do not dry properly on exterior surfaces. | But, it can be used on both exterior and interior surfaces. |

| 7. | It comes in liquid form which turns solid after application to find the materials. | These have a pasty consistency to fill the gaps between substrates. |

| 8. | They are usually over 1000 psi lap shear. The lap-shear determines the strength of aluminium to aluminium bond | These have less than 1000 psi lap shear. |

Conclusion

These construction chemicals are often used as each other’s replacements. But, this compromises the strength and functionality of the structure. So, it becomes important to understand both types of construction chemicals carefully.

The adhesion chemicals have a specific composition, features and benefits that differ greatly from that of sealants. Their application varies significantly as well.

Any information in our industry is not wholesome unless we know the availability and pricing of the material as well. So, the article also specifies the sealant and tile adhesive prices from the most sought-after manufacturers in India.

The various types of construction chemicals such as epoxy, hot melt, polymer, etc. offer numerous benefits and use like metal-to-metal bonding, glass application, tiles and wallpaper adhesives.

Many different types like silicone sealants, PU, and more are used in several areas such are wood, glass, PVC coating, and so on.

The construction chemicals come in various forms such as tapes, glue, gun, foam, etc.

With this information about the types, features, and applications of construction chemicals, along with the major differences between the two, a professional would be well placed to select the right product for a specific job. This would thus ensure that the output is more optimal, durable, and functional.

|

If you want to buy top-quality sealants from the best brands, click on the link given below to check your options and submit your inquiries:

For more details, WhatsApp us or contact below:

|