In India, Drywall is a rapidly growing concept, finding acceptance across sectors. Moreover, the gypsum plasterboard-based technology eliminates the problems faced with traditional masonry construction. Drywall partitions are lighter and deliver excellent acoustic as well as fire performance, which is something that traditional walls fail to accomplish. Drywall systems also offer moisture resistance, water resistance, mold resistance, and provision for tile & stone cladding and WC & vanity counter fixing. Unlike traditional masonry which requires curing, Drywall technology is a completely dry construction, thereby saving tremendous time in installation.

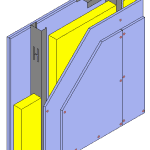

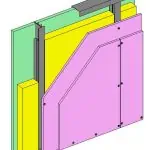

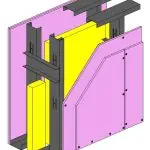

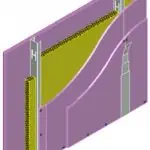

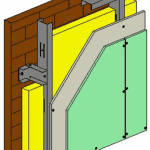

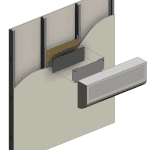

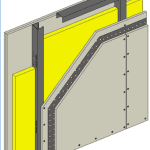

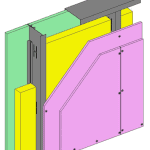

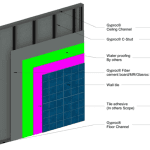

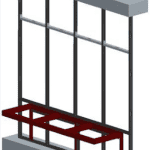

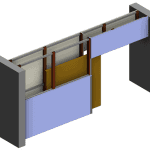

Drywalls are a high-performance lightweight interior wall system consisting of a GI steel frame, encased in gypsum plasterboards on either side attached with self-drilling Drywall screws. The joints are then taped and finished with gypsum jointing compounds.

So, get the flexibility of redesigning interiors with Gyproc Drywalls built around the existing slab of a building without the use of heavy beams.

In this article, let’s understand the various aspects related to designing Drywalls as well as how these solutions could be customized on the basis of performance requirements.

| Know more about Gyproc Drywalls. |

Factors to consider while designing Drywalls

Spaces, their design as well as performance requirements vary across sectors. Therefore, depending upon various factors, the design of Drywalls can be customized. This is possible either by customizing or working out combinations with different types of boards, the thickness as well as dimension of metal framework, the thickness of boards, spacing of framework, etc.

Depending on different factors such as application areas, acoustic performance, fire rating, floor to slab height, and loading requirements, the Drywalls could be customized.

For large spaces, the structural weight or load of internal walls is a critical design factor. Also, Drywall systems are lightweight and suitable for installation anywhere, without the requirement of a supporting beam. Moreover, if a new layout is implemented, Drywall systems can be easily dismantled and set up according to the new configuration. Additionally, Drywalls also make operations like wiring and installing service components such as switchboards, etc. easier.

Acoustic requirements play a major role while designing a certain space. The right room design and the right building material go hand in hand while delivering the right room acoustics. Moreover, Drywalls provide superior sound insulation up to 70 dB. Thus, they ensure enhanced privacy.

With Drywalls, you can experiment with a variety of different alternatives. Also, this becomes possible by using a single metal framework with single boards on both sides, two boards on both sides, or a twin frame system with a variable number of boards on both sides, among other options. This variety of solutions allows for a wide range of possibilities while still complying with thickness, cost, and performance requirements.

Following are the key principles in designing Drywalls:

Acoustic requirements

As acoustic privacy becomes more widely accepted as a fundamental contributor to indoor environmental quality, the industry is looking for practical as well as creative solutions to reduce ambient noise to improve occupant comfort.

Moreover, acoustics treatment, if predicted and dealt with properly in the Design Stage of building construction, is straightforward and inexpensive.

Wall assemblies, being the room’s largest continuous surface, are critical in achieving acceptable acoustics. Additionally, they serve as effective sound-dampeners and barriers against noise transmission between rooms if built with proper building materials.

A Drywall system is more effective than a solid concrete wall. This is because the Drywall partition works on the mass-spring-mass system. Moreover, as sound transmits through the partition, the change in medium (from Gypsum to air/Glass Wool to Gypsum) causes high transmission loss. Therefore, the sound transmitted onto the other side is much weaker.

Drywall gives the surface more mass, making it less prone to vibrate at the same frequency of sound waves, thereby, increasing the resistance to the passage of sound waves.

The passage of sound into one room of a building from a sound source located in another room or outside the building is termed ”sound transmission”.

Also, for good sound insulation, the partition must be capable of blocking airborne sound. Moreover, the construction must ensure no gaps and leaks using which sound can travel around the partition.

STC or Sound Transmission Class is a single number rating given to partitions that indicate the degree of sound transmission loss offered. Thus, a higher STC corresponds to a greater degree of sound insulation.

The acoustic requirements of a Drywall system are measured in terms of STC or Rw.

- The Sound Transmission Class (STC) or Weighted Sound Reduction Index (Rw) is a single-number rating of a material’s or assembly’s barrier effect.

- The higher the STC / Rw values, the higher will be the sound insulation of Drywall. Thus, this rating assesses the airborne sound transmission performance at a range of frequencies from 100 Hz to 4000 Hz.

- Also, a partition is rated by measuring the sound transmission loss over a range of 16 different frequencies between 100-4000 Hz.

Designed for use in walls and partition systems with a requirement of greater levels of sound insulation, Boards such as Gyproc Sound Bloc provides a high level of acoustics.

Norms and Standards for acoustics

Numerous building codes, as well as design standards, exist to identify requirements for acoustic performance to ensure the comfort of its occupants.

Gyproc Drywalls inherently provide enhanced Sound Insulation and adhere to acoustic requirement standards as per National Building Code Part 8. Moreover, the standards specific to the sector referring to NBC and other standards are as mentioned below:

Office space

Recommended sound insulation between rooms

- Room requiring privacy: 45 dB

- Conference/Discussion room: 55 dB

Healthcare

Recommended sound insulation between rooms

- Insulation between consultation room and waiting area: 45 dB

Residential

Minimum sound insulation in areas such as

- Between living room in 1 house or flat and the living room and bedroom in another: 50 dB

- Elsewhere between house and flats: 45 dB

- Between 1 room and another in the same house or flats: 35 dB

Education

Recommended sound insulation between rooms

- Assembly hall, lecture room, music room as well as typing room: 45 dB

- General classrooms, practical rooms as well as laboratories: 35 dB

- Libraries or studies: 35 dB

- Medical rooms as well as staff rooms: 45 dB

Entertainment

Maximum sound pressure levels due to external and mechanical equipment noise in auditoria

- Concert halls: dBA – 25 dB

- Drama theatres as well as cinemas: dBA – 35 dB

Hence, Gyproc Drywalls prove to be the apt solution for achieving superior acoustic performance up to 70 dB. Also, some of the standard Drywall systems and their acoustic performance are listed below:

Fire Rating requirements

With the increased construction of high-rise buildings and the establishment of new industrial zones, fire safety remains a worry due to the rising frequency of fire accidents. Fire safety becomes increasingly vital, necessitating appropriate steps to decrease the risk of fire accidents and damage.

Fire rating criteria are governed by the National Building Code. The fire rating is calculated on the basis of 3 parameters i.e., stability, integrity, and insulation.

- Stability – Firstly, the Load-bearing element must support its design load for the duration of the test.

- Integrity – The separating element must resist collapse, the occurrence of holes, gaps, or fissures through which flames, as well as hot gases, can pass and sustain flaming on an unexposed face.

- Insulation – Then, a separating element must restrict the temperature rise of the unexposed face below specified levels (140° C min temperature to 180° C max temperature).

Fires are most severe when they can’t be controlled, and a building’s structural components, notably its walls, play a key role in restricting the spread of a fire.

- The spread of fire within a building can be restricted by sub-diving it into compartments separated from one another by walls and/or floors of fire-resisting construction. Therefore, compartmentation prevents rapid fire spread as well as reduces the chance of fires becoming large.

- As per a clause from NBC, all floors shall be compartmented with the area not exceeding 750 m.sq., by a separation wall with a 2-hour fire rating.

Drywall solutions can be designed to give a fire rating of up to 4 hours of stability, integrity as well as insulation. In addition, Gyproc Fireline / FRMR boards are the preferred choice for providing fire safety in buildings.

Some of the commonly preferred fire-rated systems are listed below:

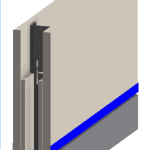

Height of the wall & Deflection requirements

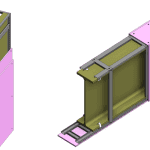

Drywall design takes into consideration the floor to slab height on respective floors. As a result, the maximum partition height of the Drywall is based on the level of lateral deflection under a given uniformly distributed load (UDL). The criterion is that the maximum lateral deflection of the partition should not exceed the L/240 criteria (where L is the partition height) when the partition is uniformly loaded to 200 Pa of wind pressure level. So, this methodology is followed for arriving at maximum partition height.

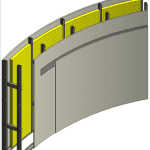

Increase the height by using a boxed stud or decreasing the stud spacing to 407mm/305mm. Moreover, the height of the Drywall depends upon the thickness of the Drywall & the spacing of studs. So, Drywalls can be built for heights up to 17 m and more.

Therefore, design Drywall partitions up to 17 m or more height with Gyproc Metal framings.

| Also see: Gypsum Drywalls – The comfort solution for interior spaces |

Duty Rating required

All Drywall partition systems have a duty rating as defined under BS 5234, part 2. So, the duty rating may vary from Light to Medium to Heavy to Severe. This rating, therefore, relates to the strength and robustness characteristics of the partition system against specific end-use.

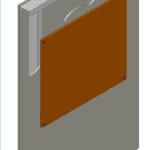

Finishes required

Showcasing versatility at its finest, Drywall partition systems provide you the option to create your own unique look for your walls. Unlike conventional walls, Drywall does not limit you to merely painting. Moreover, with gypsum Drywall, you may let your creativity flow. Drywall partition systems enable use in all internal areas of a building.

Drywall partitions impart a clean as well as sleek finish to the walls. Therefore, finishes such as paint, wallpaper, wood panels & laminates on walls up to 3/4 mm, and wall lining are possible with the Drywalls.

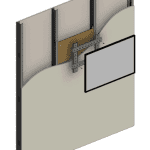

Loading requirements

Loadings constitute a very important part of constructing Drywall which varies from planned to unplanned.

Unplanned loading is done through lightweight fixtures mounted directly on the finished Drywall using specially designed fasteners. On the other hand, planned loading is done through heavyweight fixtures planned during the design of Drywall and depends on the weight per linear meter. In the case of Habito boards, hang anything on the wall using a standard 10mm wood screw, eliminating the use of ply or fasteners.

Drywalls bear static loads of fixtures and cladding such as:

Types of walls

Drywall partition systems allow creating and dividing spaces according to your needs. So, unlike conventional walls, Drywalls do not require any supporting member.

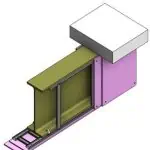

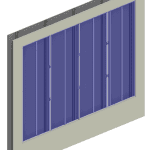

In addition, it creates possibilities for curved walls, shaft walls, secure walls, and beam & column encasements. Drywalls are also finding a strong acceptance for exterior applications. Hence, it becomes critical to understand the different types of walls, specifically critical applications while designing Drywalls.

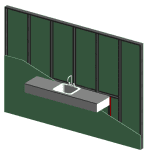

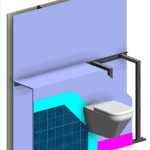

Wet area application

In any interior space, wet areas become the most critical application area. The solutions for walls require superior performance requirements such as water resistance, stone cladding, mold resistance, termite resistance, etc.

So, for wet area application, Gyproc Moisture resistant (MR Board) / Glasroc H board are preferred. Glasroc H board provides water, termite as well as mold resistance performance apart from the provision of tile/stone cladding up to 60 kg/m2.

Enabling ease of application with respect to wet areas, Drywalls are suitable for areas such as:

- Stone as well as tile cladding

- Vanity counter

- Water closet

- Shower bench

- Sliding door

Conclusion

Drywall partition systems are gaining popularity as leading solutions for achieving quality finishing with higher productivity. Besides facilitating a cleaner, quieter, and environmentally friendly worksite, Drywall construction is quicker with lesser labour requirements.

Today, all sectors such as hotels, hospitals, residential, entertainment (cinema wall), and industrial sectors use the Drywall performance partition systems. They offer a high level of acoustics (up to 70dB), provide passive fire protection (up to 4hr), high quality of interior finish, provision for loading (TV, headboard, heavy fixtures, etc.) as well as are flexible & easy to install. These parameters make life easier for the client during both the design planning and execution stage. Furthermore, Drywall systems from brands like Gyproc fulfill technical performance criteria as well as standards like BREAM, LEED, and WELL. Therefore, adopt Gyproc Drywalls and design your walls the right way with respect to future-proofing.

|

For more information on Gyproc Drywalls, Call 1800 103 7897 or write to gyprocindia@saint-gobain.com Gyproc, a part of the Saint-Gobain group, is a pioneer in the lightweight interior construction industry in India. So, the product range by Gyproc includes gypsum plasterboard systems for false ceilings and Drywall partitions, acoustical ceiling tiles, and gypsum plastering solutions. Moreover, their solutions offer comfort and sustainability to enhance the well-being of people everywhere. In addition, the firm manufactures and distributes high-performance building materials, offering creative solutions to the challenges of growth, energy efficiency, and environmental preservation. |

*The featured image used in the article is from gyproc.in

At DHIPL, we use drywalls to keep load requirements in check & reduce structural costs: Mr. Sunil Dalwadi (Interior contractors in Mumbai)

Every new building project necessitates a wide range of services, resources, and knowledge. Finding the appropriate solutions