You’ve built a beautiful building using the best material. Even the interiors look exquisite and unique. But after a few months, you get to know that the walls are chipping off and a terrible seepage issue has arisen. What went wrong? Usually, this problem comes up when one does not waterproof the buildings properly. So, waterproofing chemicals and materials for roofs, and waterproof paints, help you avoid such issues.

Water can penetrate into the building in many ways, such as rainfall, groundwater, etc. So, it is extremely important to waterproof your building. Without effective treatment, even the best buildings fail to deliver optimal performance and get damaged. Also, waterproofing is the process designed to prevent the penetration of water into the building structure. So, it is done in several stages and layers so that the building has multiple barriers. In this article, you will understand how to treat the buildings in detail.

Contents

- 1 What is waterproofing?

- 2 Types of waterproofing materials

- 3 Buy waterproofing chemicals here

- 4 FAQs

- 4.1 Which areas of my home need waterproofing the most?

- 4.2 How long does waterproofing last?

- 4.3 How is damp proofing different from waterproofing?

- 4.4 When is the best season to do waterproofing?

- 4.5 What mistakes should be avoided during waterproofing?

- 4.6 What certifications or standards should I look for in waterproofing chemical products?

- 5 13 types of cement: Uses, properties & grades explained

What is waterproofing?

Image Source: civildigital.com

Waterproofing is the method that prevents water from penetrating the building. Also, it helps keep the building dry and protects it from damage caused by moisture and water exposure. Additionally, to treat a structure, you need to use membranes and coatings to protect the surface underneath and also safeguard the structural integrity of the building. So, the multiple coatings make the “Building Envelope.” This envelope determines the performance of the building against water penetration. So, the foundation of the building must be strong.

Need for waterproofing

It wouldn’t be wrong to say that a building is a living entity that needs proper care and maintenance. Also, the issues that arise due to moisture and water must be avoided.

Water issues in the building can harm the structure in the following ways:

- Seepage through wall claddings, sills, extensions, beam-brickwork joints, etc.

- Groundwater absorption in basement spaces and flooring.

- Bursting of pipes inside the wall or under the flooring surface.

- Capillary rise through walls, joints, and columns.

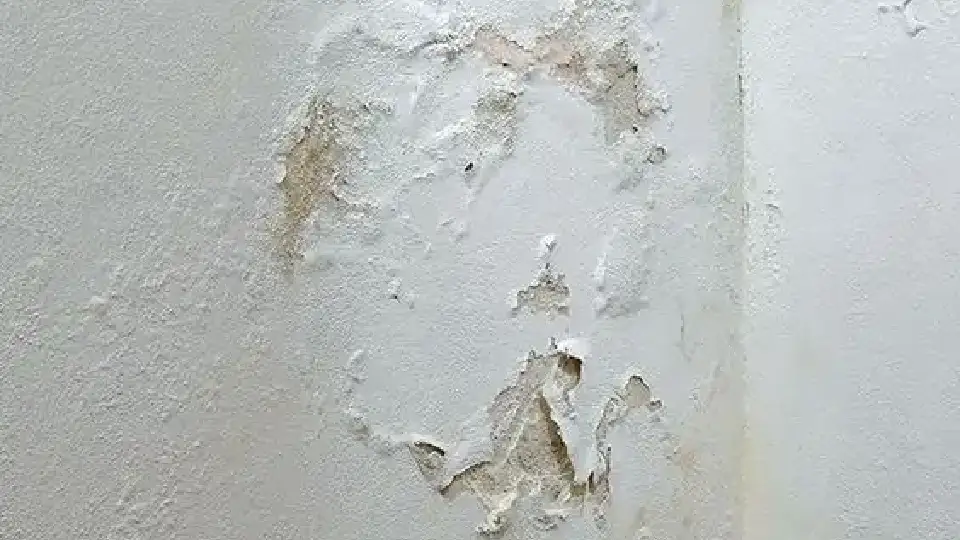

How to identify if your building has a waterproofing problem?

Image Source: selbst.com

If you see any of the following signs in your building, it needs better treatment:

- Wet and damp walls

- Growth of mould and fungi

- Rotting signs

- Pooling water

- Water leakage from the roof/ceiling

Also, all these problems can not only destroy the exterior structure of the building but also harm its interiors and core foundation. So, it is very important to treat our building properly and keep these challenges at bay.

Advantages of waterproofing

Here are the advantages of waterproofing:

- It keeps the building dry and firm.

- The building becomes more comfortable to reside in as it reduces the internal humidity.

- No damage to objects from humidity and water vapour.

- Stronger and longer-lasting building.

Types of waterproofing materials

It becomes as important to treat your building as choosing the right material for it. So, you must understand the types of waterproofing materials for your job.

Polyurethane

Image Source: coleyreedhomes.com

Polyurethane is used for waterproofing of roof. Also, the polyurethane liquid membrane offers higher flexibility, with numerous benefits such as:

- Filling of capillary cracks.

- A decrease in the concrete’s water absorbency.

- The liquid hardens the uppermost concrete surface.

Application areas

- Water tanks

- Pedestrian decks

- Balconies

- Roof

- Bridges

- Parking

Top polyurethane waterproofing companies and products

| Sr. No. | Companies and products | Price |

| 1 | Isomat Polyurethane Coating | Rs. 240/kg |

| 2 | BASF Polyurethane Membrane | Rs. 420/kg |

| 3 | Sika Polyurethane Chemical | Rs. 1650/4 l |

| 4 | Fosroc Nitoproof PU Coating | Rs. 321/l |

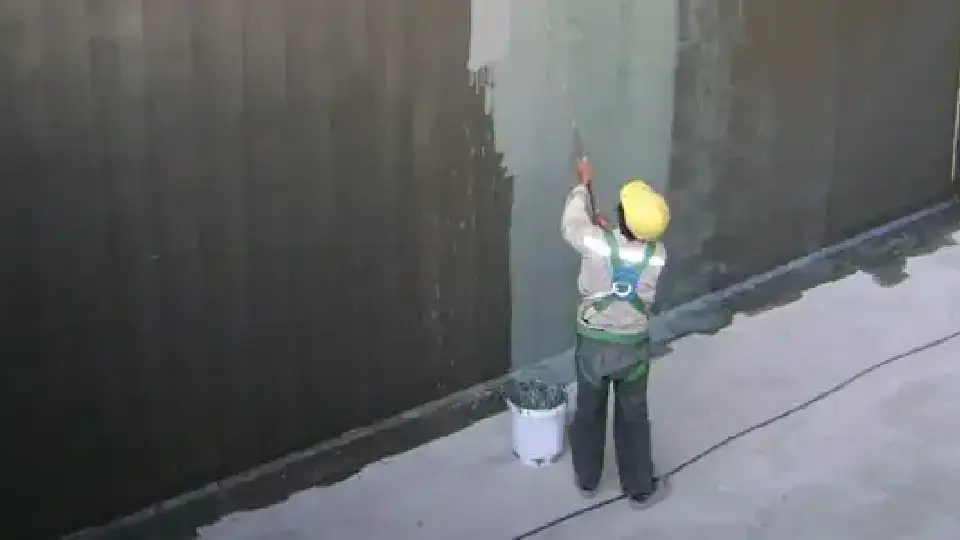

Cementitious waterproof coating

Image Source: cormix.com

This material offers the easiest application. Also, the mixture contains sand, silica-based, organic, and inorganic chemicals. Additionally, these substances, combined with lime, work as a sealant.

Application areas

- Water treatment plants

- Ports and docks

- Parking

- Tunnels

Top cementitious waterproofing companies and products

| Sr. No. | Companies and products | Price |

| 1 | Fosroc Cementitious Acrylic Coating | Rs. 150/kg |

| 2 | Cementitious Chemical by Dr Fixit Fastflex | Rs. 2700/12 kg |

| 3 | ARDEX ENDURA Cementitious Coating | Rs. 799/kg |

Bituminous waterproof membrane

Image Source: comarbois.com

Also known as bituminous coating, or asphalt coating, this membrane works effectively against water penetration. Bituminous is mixed with a sticky organic liquid. So, its viscous quality makes it an extremely powerful roof waterproofing material. The two bituminous application methods are the roll roofing material method and the roofing felt method.

The price of bituminous membranes ranges from Rs. 100 to Rs. 2000 per roll, depending upon the texture, thickness, and length of the membrane. Although the bituminous membrane offers excellent protection against water, it gets damaged by extreme temperatures and UV rays. However, when modified with acrylic or polyurethane-based polymers, it gets away with this problem.

Application areas

- Roofing systems

- Basements & foundations

- Bridges & tunnels

EPDM rubber

Image Source: polygommaindustries.com

This roof waterproofing material is a synthetic rubber material made up of propylene and ethylene. Often, professionals associate the EPDM rubber solution with a silicone compound. However, both vary in terms of chemical compositions, applications, and features. Also, EPDM rubber is very flexible and recyclable.

Application areas

- Roof

- Windows

- Wood

The price of EPDM rubber membrane ranges from Rs. 30 to Rs. 300 per square meter.

Rubberized asphalt

Image Source: aquanorthcontracting.com

Another excellent waterproof chemical, rubberized asphalt, works effectively to protect the home. Also, the strength, flexibility, and moisture vapour permeance of this material make it extremely durable and ideal for the treatment of the building.

Application areas

- Roof

- Plazas

- Parking lots

- Terrace

- Cement chemicals in various areas at the structural masonry level

Rubberized asphalt is done by experts. Therefore, the overall price varies from one service provider to another.

Thermoplastic waterproofing

Image Source: sikagroup.com

Yet another efficient waterproofing material is thermoplastic. Also, this strong solution offers protection for more than 40 years. So, its impact-resistant feature makes it ideal for all heavy-duty treatments.

Application areas

- Elevatorpits

- Decks

- Fountains

Thermoplastic is done by experts. Therefore, the overall price varies from one service provider to another.

PVC membrane

Image Source: extruflex.com

This material is commonly used for roof waterproofing. Also, its vapour-permeable property gives it additional strength. Furthermore, the base of the PVC membrane makes use of polyester mesh or glass fibre.

Application areas

- Roof

- Swimming pools

- Tunnels

- Underground structures

The price of PVC roof waterproofing membrane ranges from Rs. 1000 to Rs. 2000 per square meter.

Waterproofing paints

Image Source: theaudioart.com

The waterproof paint protects the house from environmental degradation and enhances the lifespan of the structure. Thus, it either remains water-resistant or is completely waterproof. Also, this paint can be used inside buildings in bathrooms, kitchens, basements, etc. So, it protects the bathroom and basements from leaking and excessive moisture.

Bathroom waterproof paint for walls prevents moisture from penetrating the walls. Thus, these paints are preferred over regular paints as the former will not stand up as strongly against damp conditions as the latter. Moreover, once moisture enters the walls, moulds and mildew will develop, damaging the structure as well as causing health issues.

Types of waterproofing paint

Epoxy waterproofing paint

Image Source: hometalk.com

Epoxy paints for waterproofing use strong chemicals to fight against extreme wet conditions and protect the surface. Also, they make ideal waterproof paint for roofs and terraces.

Masonry waterproof paint

Image Source: unitedgilsonitelabs.com

Made from a mixture of latex and ceramic paint, the masonry waterproof paint is generally used for roofs. Also, this paint absorbs chemicals and other liquids as easily as water and prevents them from penetrating inside. Moreover, it offers cement waterproofing chemicals.

Acrylic waterproof paint

Image Source: imapicostudio.com

This type of paint is best suited for roofs and terraces built with rectangular blocks. Also, this roof and terrace paint contracts and expels water from the surface. Additionally, this waterproof paint for the roof is non-toxic and easy to apply.

Top paint waterproofing companies and products

| Sr. No. | Companies and products | Price |

| 1 | Dulux Paints Weathershield Paint | Rs. 304/l |

| 2 | Asian Paints Apex Ultima Weatherproof Emulsion Paint | Rs. 356/l |

| 3 | Berger Paints Weathercoat Roofguard | Rs. 270/l |

| 4 | Nerolac Paints Exterior Wall Paint | Rs. 441/l |

| 5 | Perma Elastomeric Coating Paint | Rs. 536/l |

| 6 | Fosroc Liquid Nitocote Wall Guard | Rs. 360/l |

Buy waterproofing chemicals here

Asian Paints SmartCare CemBoost 200

- Type: Integral liquid waterproofing compound

- Ideal for: Strengthening the cement, concrete/plaster mix, and reducing water permeability

- Application areas: Water retaining structures, basements, roofs, slabs, screeds, bathrooms, sumps, and drains

| B U Y H E R E |

Berger WeatherCoat Roofguard

- Type: Water-based coating comprising special-quality acrylic polymer

- Ideal for: Roof waterproofing, cool roof solution, crack-bridging protection

- Application areas: Horizontal roofs, terraces, parapet walls, sloping roofs, cementitious surfaces

| B U Y H E R E |

Nippon Paint Roof Coat

- Type: Super acrylic exterior emulsion

- Ideal for: Painting and repainting asbestos and all types of roof tiles

- Application areas: Roofs, roof tiles, as well as other substrates such as metal, wood, and masonry.

| B U Y H E R E |

Pidilite Dr. Fixit LW+ Compound

- Type: Integral liquid waterproofing compound

- Ideal for: Improving cohesion, reducing permeability, enhancing workability, controlling shrinkage cracks, and resisting corrosion

- Application areas: Basements, roof slabs and screeds, water tanks, water-retaining structures, external plastering, bathrooms and balconies, and sumps and drains

| B U Y H E R E |

UltraTech Weather Pro WP+200

- Type: Integral waterproofing liquid for cement, concrete, plaster, and mortar

- Ideal for: Enhancing workability, reducing water-cement ratio, increasing cohesion and compressive strength, and preventing dampness and rusting

- Application areas: Foundation concreting, beams, columns, brick-jointing, internal and external plastering

| B U Y H E R E |

In order to retain the durability, life, and functionality of the building, it becomes essential to treat it properly. In fact, issues like seepage and mould growth can cause expensive and lifelong damage to the building. Moreover, all this also causes health hazards and puts the lives of the occupants at risk.

Also, it becomes even more important to choose the right waterproof chemical and material for the specific area of application. So, if the choice of waterproof material goes wrong, it can hamper the strength, life, and functionality of the entire building. Moreover, you must know the best type of waterproof material for each application. For instance, a bituminous membrane must not be used on the exposed terrace. On the contrary, PVC membranes, or polyurethane treatment, become more suitable here. Similarly, all types of waterproofing chemicals, such as epoxy, EPDM rubber, thermoplastics, rubberized asphalt, etc., have their unique properties and application areas.

Thus, all these minor yet extremely necessary details about waterproofing chemicals for buildings, along with price range, help the professionals make the best decisions for their projects and deliver the most flawless results.

FAQs

Which areas of my home need waterproofing the most?

Areas such as bathrooms, kitchens, basements, balconies, and terraces are the most exposed to water and moisture, and therefore, they need waterproofing the most. In addition to this, roofs and exterior walls also need proper treatment to prevent leaks and seepage during the monsoon season.

How long does waterproofing last?

The lifespan of waterproofing majorly depends on the quality of the product used and how often it is maintained. Liquid membranes and coatings last 10 years. However, sheet membranes and crystalline systems last approximately 20 years. Other than this, weather, repair frequency, and application quality also play a role.

How is damp proofing different from waterproofing?

Damp proofing prevents soil moisture and minor dampness. It is applied on the foundation walls to stop vapour but not liquid water under pressure. However, waterproofing provides a durable barrier against water infiltration. It basically prevents the building structures from leaks, seepage, and standing water.

When is the best season to do waterproofing?

The best time for waterproofing is during the summer season or before and after the monsoon season. Such a season will allow the products to cure effectively, and it will also guarantee better results. Don’t go for waterproofing in the peak monsoon season, as it will affect the drying and bonding process during product application.

What mistakes should be avoided during waterproofing?

While waterproofing, avoid using low-quality products. Also, you should not skip surface preparation, which leads to uneven coating. Furthermore, strictly avoid rushing through the curing process, as it can lead to low effectiveness. Most importantly, hire skilled applicators to ensure good waterproofing quality, thereby reducing frequent repairs and maintenance costs.

What certifications or standards should I look for in waterproofing chemical products?

While you’re buying waterproofing products, go for products that comply with international standards such as BS EN (British Standards/European Norms) and Indian standards like IS (Bureau of Indian Standards). Products with these certifications ensure durability, performance, and safety. Moreover, if you’re going for eco-friendly waterproofing products, check GreenPro or LEED compatibility levels.

*The featured image used in this article is from winklerchimica.com

13 types of cement: Uses, properties & grades explained

Cement is used as a primary binding agent in construction projects. Due to its adhesive properties, it is used as a key ingre