Epoxy resin is a uniquely versatile composite material used in the construction industry. Also, the epoxy resin contributes to the manufacture of epoxy paint, epoxy for table and floor, epoxy grout, epoxy adhesives, primers, plastics, and sealants. It is used in various construction and structural applications. Thus, epoxy’s use in these applications is often compared with conventional materials. Also, the price of epoxy resin varies according to its concentration & brand type. The excellent bonding capacity of epoxies makes them ideal for multiple uses. Also, it comes with several amazing properties and advantages. It can be used with several types of surfaces and materials. So, all of this gives epoxy an upper hand when it comes to construction chemicals. But the broad application areas and features of epoxy make it all the more important to understand its basics and details.

Contents

- 1 What is epoxy resin?

- 2 What are the applications of epoxy resin?

- 3 Epoxy resin price in India

- 4 Our top product recommendation

- 5 FAQs

- 5.1 What is the difference between epoxy and polyaspartic coatings?

- 5.2 How should I prepare my surface before applying epoxy?

- 5.3 Is it possible to customise epoxy floors with various colours or designs?

- 5.4 What are the main types of epoxy resins that are used?

- 5.5 Which is better, tiles or epoxy?

- 5.6 How long will epoxy flooring last?

- 6 Cost for epoxy flooring in India | Price range per sq ft in 2025

What is epoxy resin?

Image Source: Caplinq

Epoxy is a polymer that contains large molecules with repetitive subunits. Also, this repeating subunit molecular structure of epoxy resin offers it great elasticity, durability, and toughness. Epoxy resin is a reactive prepolymer and polymer that contains epoxide groups. These resins react either with themselves or with a variety of co-reactants such as amines, phenols, and thiols in the presence of catalysts. It is used in a wide range of industrial applications such as metal coating, floor coatings, construction chemical mixtures, countertops and tables, aircraft, etc. It outperforms other types of resin in terms of mechanical qualities, as well as heat and chemical resistance.

| Also see: Adhesives or Sealants: How to choose the right product for a specific job? (+Demo videos) |

Properties of epoxy resin

The epoxy resin comes with several properties:

- Epoxy resin has a high adhesion bond. So, it sticks to almost all building materials.

- It comes with a little possibility of shrinkage.

- Epoxy resin has gap-filling properties. So, it is an excellent construction chemical to fill gaps. This is why epoxy flooring has gained immense popularity lately.

- Its thermosetting property doesn’t allow it to melt under any temperature conditions after setting.

- Weather and chemical resistance offer epoxy resin durability.

- It is also ideal for underwater construction.

Advantages of epoxy resin

- Durability: Epoxy resin’s chemical structure gives it a lot of stability and durability.

- Strength: The strong adhesive bond and waterproofing feature offer great strength to it.

- Quick to apply: Whether it is epoxy flooring or epoxy paints, the application remains quick and easy.

- Versatility: Epoxy binds to numerous materials with the same ease. So, it makes for a compatible construction chemical.

| Also see: Top cement companies in India | Cement brands in India |

What are the applications of epoxy resin?

Epoxy resin with high adhesion and durability makes for an excellent construction chemical for building repairs. So, let us understand the major applications of epoxy resin:

Epoxy flooring

Image Source: exterior performance coatings

The epoxy floor paint and epoxy flooring are two different types of epoxy flooring treatments. Epoxy flooring has at least a 2mm thick layer of epoxy resin that offers a smooth, glossy surface. Also, the epoxy flooring material comes in many epoxy colours. Epoxy flooring makes the flooring look decorative, along with being highly durable. Also, epoxy floorings such as terrazzo epoxy flooring, chip epoxy flooring, and epoxy coloured aggregate flooring come in several epoxy flooring colours and designer patterns. You can achieve these patterns by using contrasting vinyl chips or quartz on the top epoxy flooring layer. On the other hand, epoxy floor coating has a very thin protective layer of epoxy. Also, the epoxy resin makes the floor anti-skid. So, the epoxy flooring materials can be used in bathrooms as well.

| Also see: Bathroom tiling: 23+ Tile designs and a step-by-step DIY guide |

Advantages of epoxy flooring

- Epoxy flooring paint has a shiny, high-gloss texture. So, the interiors brighten up significantly.

- The durable epoxy flooring material withstands heavy & rapid traffic.

- The application of epoxy flooring does not need any additional adhesives or equipment.

- Maintaining and cleaning epoxy flooring remains easy.

- Epoxy paint for floors lasts very long without chipping or cracking.

Epoxy 3D flooring

Another emerging flooring trend is epoxy 3D flooring. So, many malls, apartments, hotels, and even residential buildings use epoxy 3D flooring to enhance the creative element of the space. This latest fad in the decorative flooring world involves precise installation. So, a layer of self-levelling epoxy primer is laid down, followed by the desired epoxy flooring image. It is also treated with two-component epoxy resin to give the perfect depth for the epoxy 3D flooring. Finally, the epoxy 3D flooring gets a layer of protective varnish. The epoxy floor cost in India depends upon the texture, design, colour and other details. So, the 3D epoxy floor cost in India ranges from Rs. 60- Rs. 600/ square feet.

Epoxy paint

Image Source: Countertopepoxy

Epoxy paint is the most durable paint for floors and walls. It adds an extra shine to the surface. Initially, the epoxy paint was used for industrial purposes only. In fact, epoxy paint is epoxy added in latex acrylic paint. So, this epoxy paint offers the toughness and durability that you can never find in simple acrylic paint. Also, epoxy paint has chemical and corrosion-resistant properties.

Advantages of epoxy paint

- Epoxy paint offers resistance against chemicals, water, heat, shock, and corrosion.

- Painting on epoxy makes it long-lasting as the epoxy stays in place. Also, it withstands heavy traffic. So, epoxy flooring paint remains a perfect flooring choice.

- Epoxy paint offers protection against cracking, stains, wear and tear.

- The dust-resistant epoxy paint is easy to maintain.

- Epoxy resin can be used on all surfaces, such as epoxy paint for metals, etc.

| Also see: Grouting for buildings: All you need to know! (+demo videos) |

Difference between epoxy painting and epoxy coating

Professionals also get confused between epoxy paint and epoxy coating. But, both are quite different and come with different benefits:

| Sr. No. | Epoxy painting | Epoxy coating |

| 1. | It is a simple painting. (epoxy primer + epoxy paint) | It needs two elements to prepare: epoxy resin and hardener. |

| 2. | Ideal for improving the look of the epoxy flooring. | Best for floors with the risk of chemical spillage and heavy traffic. |

| 3. | Epoxy painting is more durable than normal acrylic paint. But it cannot withstand chemicals, abrasions, and stains. | It can withstand all kinds of stains and abrasions. |

| 4. | Cheaper | More expensive. |

| 5. | Quick application. | Slightly complex application. |

The epoxy resin paint price range varies from Rs. 150 to Rs. 3000.

Epoxy grout

Image Source: fireclay tile

The epoxy grout is used for multiple purposes. So, epoxy grouting can adhere to a wide range of materials such as plastic, metals, ceramics, rubber, etc.

Advantages of epoxy grout for tiles:

- Tile epoxy grout offers a stain-free, easy-to-clean look.

- Epoxy grouting for tiles is chemical-resistant, non-toxic, and dirt-resistant.

- Tile with epoxy grout does not crack. So, the gaps become impermeable after epoxy grouting.

- You do not need an additional sealer once you’ve used epoxy grout for tiles.

- The epoxy colour of the epoxy grout for tiles comes in various options. Also, it does not lose its shine or discolour over time.

Epoxy grout for tiles makes for an ideal grouting solution. So, tile with epoxy grout is better than cement for various reasons:

| Sr. No. | Epoxy grouting for tiles | Cement for tiles |

| 1. | Epoxy grouts do not shrink, crumble, or crack. | Shrinks over time. |

| 2. | Epoxy grouting for tiles offers strength for high traffic. | Not ideal for dense traffic conditions. |

| 3. | Highly resistant grouting material. | But, highly porous cement does not give any resistance against chemicals and liquids. |

| 4. | Easy to maintain | Difficult to clean/ remove stains |

| 5. | Epoxy colours come in a wide variety. Moreover, epoxy grout for tiles does not discolour. | Additional painting is required for colour. It discolours over time. |

Epoxy grouting price

| Sr. No. | Brand and product | Epoxy grouting price per kg |

| 1. | Asian Paints epoxy SmartCare Tile Grout | Rs. 773/kg |

| 2. | Roff Pidilite Rainbow Tile Epoxy Grout | Rs. 1130/kg |

| 3. | Dr Fixit Epoxy Bonding Agent | Rs. 794/kg |

| 4. | MYK Laticrete Epoxy Grout | Rs. 750/kg |

| 5. | BASF Master Flow 410 Epoxy Resin Grout | Rs. 100 kg |

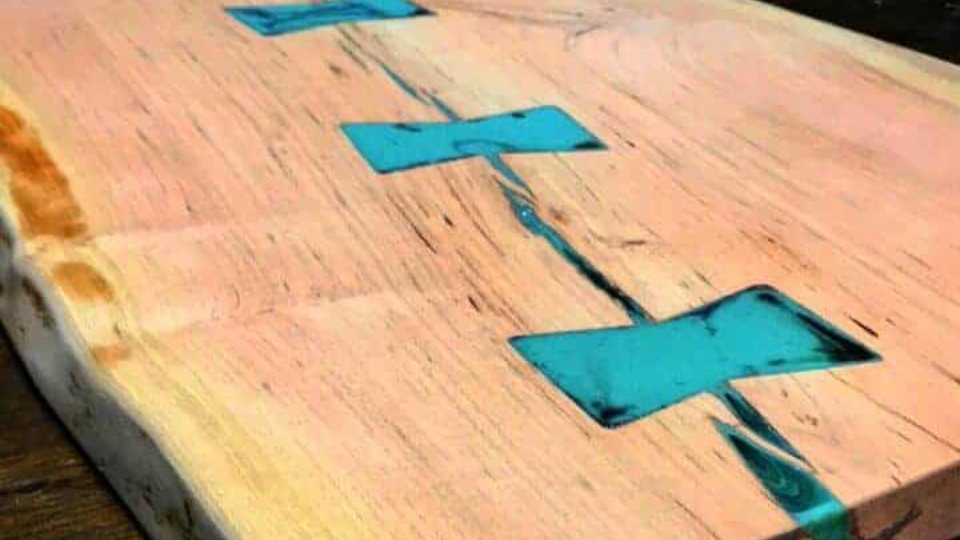

Epoxy tabletop

Image Source: bodyartstyle

The epoxy tables give an extremely luxurious and unique look to the interiors. Also, this retrofit construction chemical-epoxy resin can be applied to existing tabletops and countertops as well. You can use epoxy tabletop resin to restore worn-out countertops in kitchens and bathrooms.

You can use epoxy for tables over the following materials:

- Laminate

- Formica

- Ceramic

- Concrete

- Wood

- Metal

Marbles and granite countertops have their own beauty. So, most people do not like to cover them with this construction chemical. But epoxy for tables can be used with these materials as well.

Advantages of the epoxy tabletop

- Durable finish.

- High-gloss epoxy tables look.

- Chemical, heat, and water-resistant.

- Endless design possibilities.

- Non-toxic.

- Easy to maintain

Epoxy waterproofing

Image Source: Nbm&Cw

The adhesive strength of epoxy offers excellent waterproofing to this construction chemical. Also, the epoxy paint contains a waterproofing feature. So, you get a chemical-resistant finish that can easily last for up to 10 years even in pools and bathroom floors, bathtubs, etc.

Epoxy resin for wood

Image Source: Lazy Guy DIY

Wood epoxy is just like regular epoxy with a minor difference in features for woodworking. So, it must remain bubble-free, moisture-resistant, and thin. Thus, this epoxy resin for wood makes excellent use in furniture such as tabletops and more. Epoxy is also waterproof and seals the wood. You can give it a transparent, metallic, or opaque epoxy colour.

Epoxy resin price in India

| Sr. no. | Brands and Products | Epoxy Resin Price |

| 1. | Hakson’s epoxy resin and hardener | Rs. 949/1.5 kg |

| 2. | Loctite Tough X epoxy resin and hardener | Rs. 1060/ 1.8 kg |

| 3. | Araldite Epoxy resin and hardener price | Rs. 2600/1.8 kg |

| 4. | Fosroc Nitocote ET140 Epoxy resin | Rs. 699/ container |

| 5. | Sika Epoxy Resin | Rs. 525/kg |

Our top product recommendation

Haksons Resin & Hardener – High Gloss Epoxy Resin Clear Coat

LAPOX ULTRA FIX EPOXY ADHESIVE

MYK Laticrete LATAPOXY® Dazzle Grout

Ecopoxy UVPoxy

Araldite Standard Epoxy Adhesive

Epoxy resin comes with several benefits and an affordable price range. Also, this synthetic construction chemical is used in the manufacture of substances such as paints, coatings, and other materials. Moreover, the numerous advantageous properties of this chemical, such as durability, resistance against chemicals, water, corrosion, dirt, etc., make it ideal for building and construction. So, the applications of epoxy on paints, flooring, grouting, and countertops make them long-lasting and durable. Also, the professionals can choose this versatile construction chemical for the right job with information about the specifications, advantages, applications, and price range of the construction chemical, like epoxy resin. All this would benefit both the professionals and the clients and help them get high-performing, durable results.

FAQs

What is the difference between epoxy and polyaspartic coatings?

Epoxy and polyaspartic coatings are both systems that are used to protect concrete. However, their properties differ in many ways. Epoxy is more traditional with a long curing time, whereas polyaspartic coatings are a newer and more advanced coating that cures in just a few hours. Additionally, Epoxy is less costly than Polyaspartic coatings.

How should I prepare my surface before applying epoxy?

Preparing your floor before applying epoxy is a crucial part of receiving a smooth, durable, bubble-free finish. Firstly, clean the surface thoroughly, sand the surface if needed, and fill cracks or holes if any. Always ensure that the floor is moisture-free. Now apply seal coat if it is recommended. Finally, the surface is ready to begin applying epoxy.

Is it possible to customise epoxy floors with various colours or designs?

Yes, you can add colours by mixing pigments or dyes directly into resin. Moreover, different colours can be swirled together to create marble-like 3D effects. Moreover, you can also give your surface a glossy, matte, satin or textured finish. You can also create custom designs by using various objects such as shells, stones, fabrics, or photos.

What are the main types of epoxy resins that are used?

Epoxy resin is available in various types, each designed for a specific purpose. The main epoxy resins that are used across industries are BPA-based epoxy resin, BPF-based epoxy resin, Novolac epoxy resin, Aliphatic epoxy resin, Glycidyl Amine epoxy resin, Waterborne epoxy resin, Solid epoxy resin, and Cyloaliphatic epoxy resin.

Which is better, tiles or epoxy?

Choosing between tiles and epoxy depends upon several factors like budget, durability, purpose and surface. Epoxy resin is more durable and customizable. In contrast, tiles are prone to cracks and are not customizable. Additionally, epoxy resin has easy maintenance when compared to tiles, as they require regular grout cleaning.

How long will epoxy flooring last?

The life of epoxy flooring depends on several factors, including the quality, maintenance, quality, and installation process. Usually, epoxy flooring lasts up to 15 years, but heavy-duty epoxy flooring can last up to 25 years. However, proper grinding, cleaning, and priming can ensure a longer lifespan.

*The featured image used in this article is from mapleconcretepumping.com

Cost for epoxy flooring in India | Price range per sq ft in 2025

Due to the durability, beauty, and maintenance-free nature of epoxy floorings, their popularity is rising in both residential